Recent Product Posts

Titanium steel composite plate refers to a metal composite plate in which titanium with good corrosion resistance is plated on the surface of ordinary steel plates.

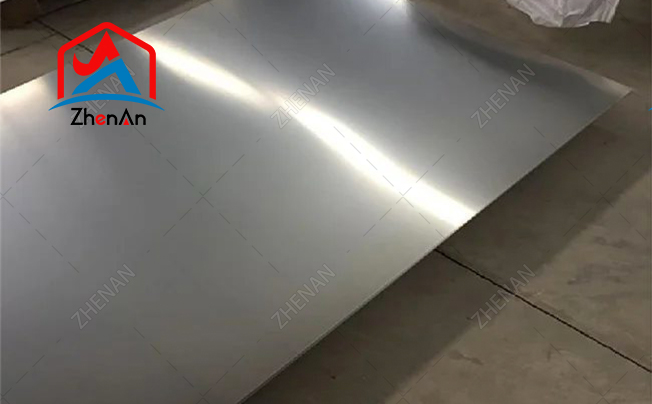

Titanium Steel Composite Plate

Titanium Steel Composite Plate Description

Titanium steel composite plate refers to a metal composite plate in which titanium with good corrosion resistance is plated on the surface of ordinary steel plates. It not only has the strength of ordinary steel plates as a structure, but also has the corrosion resistance of titanium metal. The most important thing is that the cost is greatly reduced, so it is widely used in various fields.

Titanium Composite Steel Plate Parameters

| Product Name | Titanium Clad Steel Plate |

| Cldding Material Scope | Titanium(Gr1, Gr2, Gr3,Gr5, Gr9,Gr7, Gr11, Gr12, etc),Stainless Steel, Non-ferrous metals (aluminum,copper,nickel,zirconium,tantalum) |

| Titanium Type of the Clad | Ti-steel clad plate,Ti-stainless steel clad plate,Ti-aluminum clad plate,Ti-copper clad plate,Ti-nickel clad plate |

| Technique | Explosive welding, Hot rolling |

| Standard | ASTMB898, NB/T47002.3-2010 |

| Overall Thickness | 8-120mm |

| Cladding thickness | 2-15mm |

| Width | 3000mm or Customizable |

| Length | 8000mm or Customizable |

| Surface Treatment | Polished |

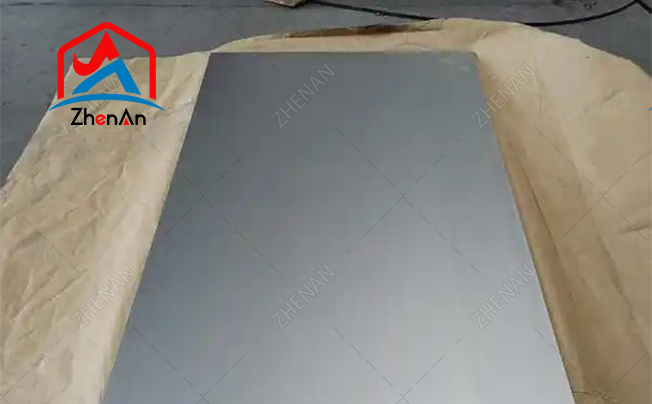

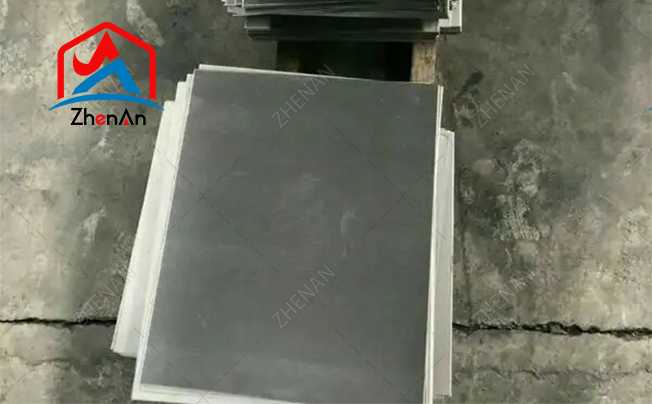

| Package | Export sea worthy package + waterproof paper + wooden pallets |

| Delivery | Normally 10 days after receiving the 30% deposit |

| Payment | T/T, L/C, DP or Negotiable, For Russia Market |

| Applications | Petroleum, Petroleum refining, chemical industry, light industry, electrolytic |

| Aluminium, food, Seawater desalination, Water conservancy | |

| Hydropower, Nuclear energy, Marine, Medical | |

| Aerospace, Environmental protection field |

Titanium Composite Steel Plate Manufacturing

There are three main manufacturing methods for titanium composite steel plates, namely explosive cladding method, thick plate rolling method and continuous hot rolling method. Titanium composite steel plates manufactured by explosive cladding and thick plate rolling methods are thick plates and are mainly used as corrosion-resistant building materials. Titanium composite steel plates manufactured by continuous hot rolling are thin plates, and their main application areas are marine civil engineering.

Application Fields Of Titanium Composite Steel Plates

Petrochemical and chemical container equipment manufacturing is the traditional application field of titanium composite steel plate materials, and its usage always ranks first. Titanium has good stability in various acid, alkali and salt media in the chemical industry. Therefore, titanium composite steel plates play an irreplaceable role in refineries and chemical plants.

Titanium and its alloys have excellent resistance to corrosion by seawater, chloride solutions and fluid erosion. The evaporation chamber made of titanium composite steel plates has good effects on slowing down corrosion, preventing scaling of the evaporation tank wall, extending the production cycle, and improving the quality of salt, which greatly reduces the cost of using salt plant equipment.

Titanium and titanium alloys have excellent resistance to seawater, chloride solution corrosion, and fluid erosion properties, and titanium is non-toxic and harmless, which makes titanium composite steel plates an ideal material for seawater desalination equipment.

Titanium composite steel plates with thick cladding (multi-layer ≥8mm) and large plate width (single area ≥20m) are the main materials for condenser tube sheets in nuclear power equipment. They are in great demand and have broad application prospects.

Titanium Composite Steel Plate Properties

Titanium composite steel plate has excellent corrosion resistance and strength, making it an ideal material for manufacturing equipment in corrosion-resistant environments. As the production process of titanium composite steel plates continues to improve, its applications will become more extensive and common.

FAQ

Q: What information should I let you know if i want to get a quotation?

A: The required material dimension (Thickness*Width*Length, diameter*length; if possible, please kindly supply us drawings).

The required items more information, such as Surface Condition, Tolerance Request, The Quantity, and other mechanical and technical details.

If it is possible, please also provide the application of products, we will recommend the most suitable products with details for confirmation.

Q: Do you inspect the finished products?

A: Yes. Each step of production and finished products will be carried out inspection by QC department before storing in the finished goods warehouse. NG goods are not allowed in the completed goods warehouse.

Q: Can you guarantee the prompt delivery?

A: Yes, Per our experience, when we get your inquiries, not only we will evaluate the more competitive price, but also we can get the most reasonable delivery time. So the prompt delivery can be guaranteed.

Q: What is the shipping cost?

A: The shipping cost is determained by the destination port, weight, packing size, total CBM of the

products, we will try best to get the most reasonable shipping cost from the forwarders or express couriers to help you save more money.

Q: How about your payment terms?

A: We have flexible payment terms such as L/C; T/T; Western Union; D/P(Document Against Payment); etc.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.