Recent Product Posts

Tantalum (Ta) is a refractory metal. Tantalum is quite soft compared to tungsten or even molybdenum. Tantalum's density and melting point are between those of tungsten and molybdenum.

Tantalum Products

Tantalum Products describe

Tantalum (Ta) is a refractory metal. Tantalum is quite soft compared to tungsten or even molybdenum. Tantalum's density and melting point are between those of tungsten and molybdenum.

Tantalum is commonly used in capacitors or other electronic devices, and is also used to make alloys of other metals. Its high corrosion resistance can be used in chemical reaction pipes and vessels such as vacuum furnaces and nuclear reactors, providing corrosion resistance at high temperatures while minimizing product contamination. Its high thermal conductivity can be used in equipment such as heat exchangers and distillation equipment.

Tantalum product parameters

| Tantalum Sheet / Tantalum Plate | ||

| .002″ x 6″ x 12″ | .040″ x 12″ x 24″ | .500″ x 12″ x 24″. |

| .004″ x 12″ x 24″ | .050″ x 12″ x 24″ | .625″ x 12″ x 24″ |

| .005″ x 12″ x 24″ | .060″ x 12″ x 24″ | .750″ x 12″ x 24″ |

| .010″ x 12″ x 24″ | .080″ x 12″ x 24″ | 1.00″ x 12″ x 24″ |

| .015″ x 12″ x 24″ | .125″ x 12″ x 24″ | 1.50″ x 12″ x 24″ |

| .020″ x 12″ x 24″ | .188″ x 12″ x 24″ | 2.00″ x 12″ x 24″ |

| .025″ x 12″ x 24″ | .250″ x 12″ x 24″ | 2.50″ x 12″ x 24″ |

| .030″ x 12″ x 24″ | .375″ x 12″ x 24″ | 3.00″ x 12″ x 24″ |

| Tantalum Bar / Tantalum Rod | ||

| .125″ dia x 72″ | .750″ dia x 72″ | 2.25″ dia x 72″ |

| .188″ dia x 72″ | .875″ dia x 72″ | 2.50″ dia x 72″ |

| .250″ dia x 72″ | 1.00″ dia x 72″ | 3.00″ dia x 72″ |

| .375″ dia x 72″ | 1.25″ dia x 72″ | 3.50″ dia x 72″ |

| .500″ dia x 72″ | 1.50″ dia x 72″ | 4.00″ dia x 72″ |

| .625″ dia x 72″ | 2.00″ dia x 72″ | |

| Tantalum Ribbon Slit To Size: (Thickness) | ||

| .002″ | .005″ | .008″ |

| .003″ | .006″ | .010″ |

| .004″ | .007″ | .015″ |

| Tantalum Tubing / Tantalum Pipe: | ||

| .125″ od x .015″ wall x 72″ | .375″ od x .015″ wall x 72″ | .750″ od x .020″ wall x 72″ |

| .188″ od x .015″ wall x 72″ | .375″ od x .020″ wall x 72 | 1.00″ od x .020″ wall x 72″ |

| .188″ od x .020″ wall x 72″ | .500″ od x .015″ wall x 72″ | 1.50″ od x .030″ wall x 72″ |

| .250″ od x .015″ wall x 72″ | .500″ od x .020″ wall x 72″ | 2.00″ od x .030″ wall x 72″ |

| .250″ od x .020″ wall x 72″″ | .625″ od x .020″ wall x 72″ | 2.00″ od x .065″ wall x 72″ |

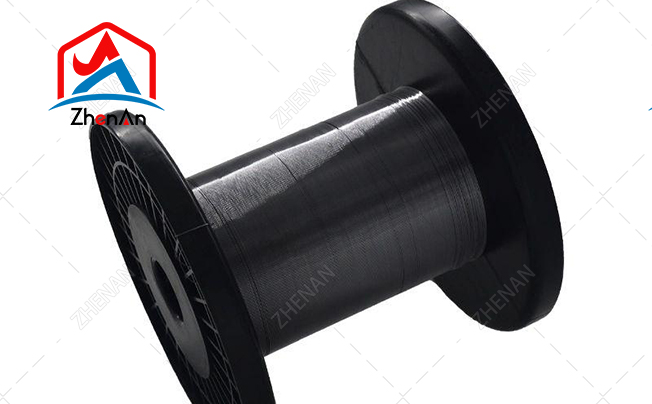

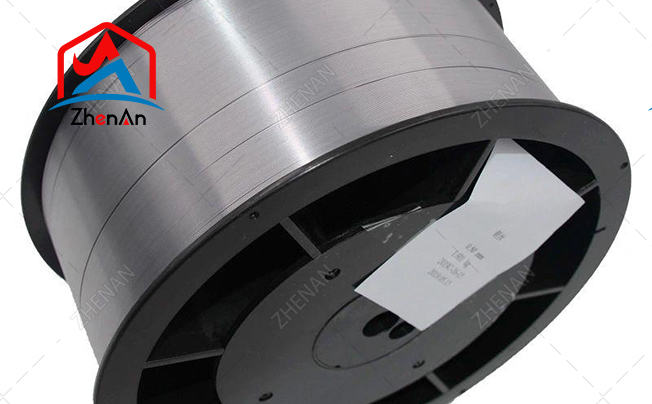

| Tantalum Wire: | ||

| .003" x 50 ft coil | .030" x 50 ft coil | .050" x 50 ft coil |

| .005" x 50 ft coil | .031" x 50 ft coil | .059" x 50 ft coil |

| .010" x 50 ft coil | .035" x 50 ft coil | .060" x 50 ft coil |

| .015" x 50 ft coil | .039" x 50 ft coil | .0625" x 50 ft coil |

| .020" x 50 ft coil | .040" x 50 ft coil | |

| .025" x 50 ft coil | .047" x 50 ft coil | |

| Tantalum Foil / Tantalum Strip (Thickness) | ||

| 0.008 mm | 0.025 mm | 0.03mm |

| 0.050 mm | 0.07 mm | |

| Tantalum Crucible (Capacity) | ||

| 1000 ml | 100 ml | 10 ml |

| 15 ml | 20 ml | 25 ml |

| 35 ml | 45 ml | 55 ml |

| 5 ml | 75 ml | |

| Metallurgical Grade Tantalum Powder (Particle size) | ||

| -60 mesh | -200 mesh | -325 mesh |

| Tantalum Mesh | ||

| 1.2mm x 1000mm x 2000mm in coil | ||

| Tantalum Wire Mesh | ||

| 10mm-2000mm | ||

| Tantalum Disc (Thickness) | ||

| .001″ to .004″ | .005″ to .020″ | .021″ to .032″ |

| .034″ to .120″ | .125″ to .250″ | |

| Tantalum Sputtering Target | ||

| 1.00" Dia. x 0.125" Thick | 1.00" Dia. x 0.250" Thick | 2.00" Dia. x 0.125" Thick |

| 2.00" Dia. x 0.250" Thick | 3.00" Dia. x 0.125" Thick | 3.00" Dia. x 0.250" Thick |

| 4.00" Dia. x 0.125" Thick | 4.00" Dia. x 0.250" Thick | 6.00" Dia. x 0.250" Thick |

| 8.00" Dia. x 0.125" Thick | 8.00" Dia. x 0.250" Thick | |

| Tantalum Ingot | ||

| 70-195 mm Dia. | ||

| Tantalum Capillary | ||

| OD: 0.31-35.00 mm | WT: 0.08-1.00 mm | |

| Capacitor Grade Tantalum Powder | ||

| 4V-40V | 20V-60V | above 60V |

| Tantalum Lump | ||

| 10mm | 9mm | |

| Capacitor Grade Tantalum Wire | ||

| 0.2mm | 0.3mm | |

| Tantalum Marker Bands | ||

| Diameter: 0.2 ~ 8mm | Wall Thickness: 0.015 ~ 0.5mm | |

| Spherical Tantalum Powder | ||

| 50nm | 10nm | |

| Tantalum Flange | ||

| Tantalum Heat Element | ||

| Tantalum Single Crystal | ||

| Tantalum Tube/Tantalum Pipe | ||

| Tantalum Tungsten Foil/Strip | ||

| Tantalum Tungsten Sheet/Board | ||

| Tantalum Tungsten Tube/Pipe | ||

| Tantalum Tungsten Rod/Bar | ||

| Tantalum Tungsten Wire | ||

| Tantalum Tungsten Disc | ||

| Tantalum Niobium Alloy Foil/Strip | ||

| Tantalum Niobium Alloy Sheet/Board | ||

| Tantalum Niobium Alloy Tube/Pipe | ||

| Tantalum Niobium Alloy Rod/Bar | ||

| Tantalum Niobium Alloy Wire | ||

| Tantalum Niobium Alloy Disc | ||

| Capacitor Grade Tantalum Powder (4V-40V) | ||

| Capacitor Grade Tantalum Wire | ||

| Capacitor Grade Tantalum Powder (20V-60V) | ||

| Capacitor Grade Tantalum Powder (above 60V) | ||

| Tantalum Tungsten (Ta10W) Alloy Products | ||

| Tantalum Tungsten (Ta2.5W) Alloy Products | ||

| Specific lengths and sizes available upon request. | ||

Name: Tantalum plate, tantalum sheet, tantalum strip, tantalum foil

Tantalum Products Usage: Used to make heating parts, heat-insulating parts and charging vessels for vacuum blast furnaces. In the chemical industry, it can be used to make cookers, heaters, coolers, various utensils and devices, etc., as well as in aviation, aerospace industry, medical equipment, etc. It has wide application in fields.

Niobium and tantalum products mainly include: tantalum powder, niobium powder, tantalum wire, ingots, rods, plates, tubes, sheets, etc.

Advantages of Tantalum Products

High density and melting point

High corrosion resistance

High thermal conductivity

Applications of Tantalum Products

capacitor or electronic device

chemical reaction tube

nuclear reactor

heat exchanger

Distillation equipment

Application of tantalum and niobium metal materials

The applicable fields of application of new tantalum and niobium materials include: electronics, precision ceramics and precision glass industries; electroacoustic and optical devices; cemented carbide, aerospace and electronic energy industries; biomedical engineering; superconducting industry; special steel and other industries.

In the electronics industry, tantalum metal can be used to manufacture electrolytic capacitors, which have outstanding characteristics such as large capacitance, small leakage current, good stability, high reliability, good voltage resistance, long life, and small size.

In addition, tantalum is also widely used in electronic circuits of national defense, aviation, aerospace, electronic computers, high-end civilian appliances and various electronic instruments.

In the metallurgical industry, tantalum and niobium are mainly used as additives to produce high-strength alloy steel, improve the properties of various alloys, and make super-hard tools.

【About delivery】

We will ship the goods to you when the cooperation method is confirmed and the cooperation is concluded.

We have dedicated personnel to strictly check the quality of the goods during delivery and packaging, so please feel free to purchase.

【About cooperation】

In line with the service tenets of excellence in production, honesty and trustworthiness in distribution, warm and thoughtful service, and the founding spirit of assisting partners to achieve their careers and thereby achieving their own careers, we provide customers with excellent quality and services.

Our service tenet: integrity first, customer satisfaction, mutual benefit and win-win.

Our production philosophy: quality first, excellence, pragmatism and innovation.

We always adhere to technological innovation, continuous quality improvement, always maintain quality, and pursue brand support. All employees of the company and colleagues from all walks of life work together to seek prosperity and common progress for China's nonferrous metals.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.