Definition of molybdenum in metal

Molybdenum, a chemical element denoted by the symbol Mo and atomic number 42, holds a distinguished place among the transition metals in Group 6 of the periodic table. Renowned for its remarkable attributes, including a lofty melting point, robustness, and exceptional corrosion resistance, molybdenum frequently assumes the role of an alloying element in diverse metals, thereby augmenting their properties. Its introduction into metal alloys bestows upon them heightened hardness, tensile strength, and fortitude against heat and wear. Moreover, molybdenum's capacity to endure extreme temperatures renders it an indispensable constituent in sectors such as aerospace, defense, and industrial processes.

Explanation of molybdenum as a chemical element

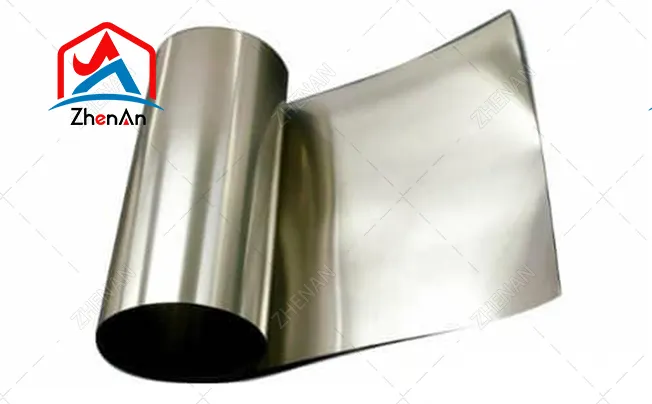

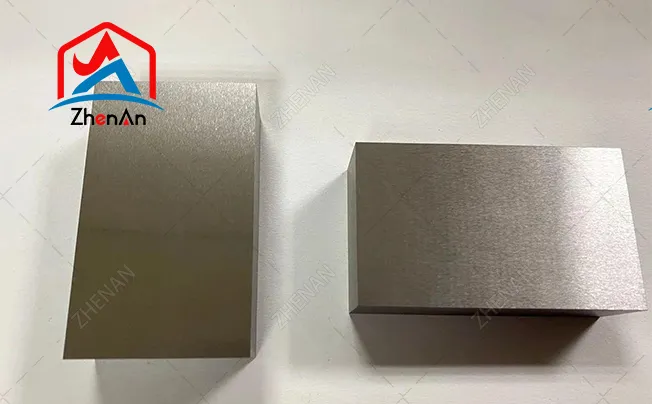

Molybdenum, an opulent silvery-white metal, is a rarity in nature. Its discovery traces back to the waning years of the 18th century when the sagacious Swedish chemist, Carl Wilhelm Scheele, first espied its existence. The illustrious Peter Jacob Hjelm later succeeded in isolating this prodigious element. Derived from the Greek term "molybdos," signifying "lead-like," molybdenum owes its nomenclature to its uncanny resemblance to the aforementioned metal. Possessing an elevated density and an extraordinary melting point of 2,623 degrees Celsius, molybdenum stands as one of the most refractory elements known to mankind. Notably, it boasts an unparalleled corrosion resistance, remaining impervious to the influences of oxygen and water at ambient temperatures. The primary source of molybdenum lies in molybdenite ore, which manifests in various pockets across the globe.

Introduction to molybdenum's role in metal

Molybdenum, owing to its exceptional attributes and versatility, occupies a pivotal position within the realm of metallurgy. Its introduction into other metals, such as steel, iron, nickel, or titanium, engenders the formation of alloys that are both robust and enduring. These molybdenum-infused alloys boast heightened strength, hardness, and resistance to deformation, rendering them eminently suitable for employment in the domains of construction, automotive engineering, and machinery. Additionally, molybdenum augments the corrosion resistance of stainless steels, rendering them ideal for deployment in arduous environments such as those encountered in marine or chemical processing. Furthermore, the inclusion of molybdenum within metal alloys imparts an enhanced ability to withstand soaring temperatures, thereby rendering them indispensable in the spheres of aerospace, power generation, and electronics.

What does molybdenum do to metal?

This is a question that has perplexed many a scholar and scientist. Molybdenum, a rare and precious element, possesses remarkable properties that can greatly enhance the strength and durability of metal.

In the realm of metallurgy, molybdenum is hailed as a true wonder. When added to steel, it bestows upon it an unparalleled toughness and resistance to corrosion. This makes it an invaluable component in the production of high-strength alloys, such as those used in aircraft and automotive industries.

But what exactly is it about molybdenum that grants it such power? Its atomic structure holds the key. Molybdenum atoms, with their unique arrangement of electrons, form strong bonds with other metal atoms, effectively reinforcing the overall structure.

Furthermore, molybdenum has the remarkable ability to withstand incredibly high temperatures. This makes it an ideal choice for applications in extreme environments, such as jet engines and nuclear reactors.

Indeed, molybdenum is a true game-changer in the world of metal. Its presence can transform ordinary steel into a material of extraordinary strength and resilience. It is no wonder that scientists and engineers continue to explore the vast potential of this remarkable element.

III. Heat resistance and high-temperature applications

Molybdenum, esteemed for its extraordinary heat resistance and lofty melting point, finds wide usage in various high-temperature applications. Its remarkable thermal conductivity renders it an ideal choice for industries that necessitate materials capable of enduring extreme temperatures. Molybdenum's melting point, soaring to 2,623 degrees Celsius (4,753 degrees Fahrenheit), enables it to retain its vigor and integrity even amidst elevated temperatures, thus rendering it eminently suitable for demanding environments.

A. Molybdenum's high melting point and thermal conductivity

Molybdenum possesses one of the highest melting points among all metallic elements, endowing it with exceptional heat resistance. With a melting point surpassing 2,600 degrees Celsius (4,700 degrees Fahrenheit), molybdenum remains steadfast and maintains its structural stability amidst exceedingly high temperatures. Moreover, molybdenum exhibits excellent thermal conductivity, signifying its ability to efficiently transfer heat devoid of deformation or loss of properties. This amalgamation of a high melting point and thermal conductivity renders molybdenum an indispensable material in numerous high-temperature applications.

B. Examples of molybdenum's use in high-temperature environments

Molybdenum finds extensive utilization in a vast array of high-temperature environments across diverse industries. Its exceptional heat resistance and other advantageous properties render it an essential component in applications such as aerospace engineering, power generation, electronics, and metalworking. In the realm of aerospace, molybdenum is employed in rocket nozzles, turbine blades, and other components that confront extreme temperatures during space exploration and aviation. The power generation sector harnesses molybdenum in thermal power plants, nuclear reactors, and solar energy systems due to its ability to withstand the intense heat engendered in these environments. Molybdenum's high-temperature resistance also proves invaluable in electronics manufacturing, where it finds utility in semiconductors, heating elements, and electrical contacts. Furthermore, in metalworking processes like forging, extrusion, and casting, molybdenum is utilized for its heat resistance and capacity to endure molten metals.

Molybdenum's Influence on Metal: A Catalyst's Role

Molybdenum, a wondrous transition metal possessing unique qualities, serves as a most effective catalyst in diverse refining and manufacturing processes of metal. Its catalytic attributes stem from its remarkable ability to facilitate chemical reactions by lowering the activation energy required for their occurrence. This is achieved through the formation of stable intermediates, which enhance the pace and efficiency of reactions. Molybdenum's catalytic prowess is particularly invaluable in the production of metals, where it plays a vital role in augmenting the efficiency and quality of the refining and manufacturing processes.

Elucidation of Molybdenum's Catalytic Attributes

Molybdenum exhibits excellent catalytic properties owing to its distinctive electronic structure and surface reactivity. As a catalyst, it can engage in redox reactions with ease, readily accepting and donating electrons, thereby facilitating the transfer of reactants and intermediates. Moreover, molybdenum-based catalysts possess remarkable thermal stability and resistance to harsh operating conditions, rendering them suitable for various industrial applications. The presence of molybdenum in catalysts can also influence the selectivity and specificity of reactions, enabling the production of desired metal products with enhanced purity and properties.

Applications of Molybdenum as a Catalyst in Refining and Manufacturing Metal

Molybdenum finds extensive use as a catalyst in the refining and manufacturing processes of metal. In the production of steel, for instance, molybdenum-based catalysts are employed during the desulfurization process to eliminate impurities and enhance the mechanical properties of the ultimate product. Molybdenum catalysts are also utilized in the manufacturing of petrochemicals, where they aid in the conversion of hydrocarbons into valuable intermediates for various industrial applications. Furthermore, molybdenum's catalytic properties are harnessed in the production of non-ferrous metals such as copper and nickel, contributing to improved yields, energy efficiency, and overall process sustainability.

Health and Safety Considerations of Molybdenum in Metal

Exposure to molybdenum, a widely used metal in various industries, can pose potential health risks. It is important to understand these risks and take appropriate safety precautions when handling molybdenum-treated metals. Molybdenum exposure can occur through inhalation, ingestion, or skin contact, and its health effects depend on the level and duration of exposure. Studies suggest that high levels of molybdenum in the workplace may lead to respiratory issues, such as asthma and bronchitis. Long-term exposure to elevated levels of molybdenum has also been associated with kidney and liver damage. Therefore, it is crucial to implement safety measures to minimize the risks associated with molybdenum exposure.

Overview of Potential Health Risks Associated with Molybdenum Exposure

Molybdenum, a metal of great utility in various industries, can have dire consequences on one's health if not handled with care. Inhaling molybdenum dust or fumes can irritate the delicate respiratory system, leading to distressing symptoms such as coughing, wheezing, and breathlessness. Prolonged exposure to high levels of molybdenum in the air may even result in chronic respiratory conditions, causing great discomfort and hindering one's ability to breathe freely. Furthermore, ingesting molybdenum through contaminated food or water sources can bring about distressing gastrointestinal disturbances, including bouts of nausea, vomiting, and debilitating diarrhea. The long-term ingestion of excessive molybdenum can wreak havoc on the kidneys, impairing their function and potentially leading to the formation of painful kidney stones. Alas, the liver too is not spared from the pernicious effects of molybdenum exposure, as studies have indicated a worrisome connection between this metal and liver damage, including the insidious development of hepatotoxicity and liver fibrosis.

Safety Precautions and Regulations for Handling Molybdenum-Treated Metals

Given the potential health risks associated with molybdenum exposure, it is of utmost importance to diligently observe safety precautions and adhere to stringent regulations when handling molybdenum-treated metals. Employers, in their wisdom, should provide their workers with the necessary personal protective equipment (PPE), including respiratory masks, gloves, and protective clothing, to shield them from direct contact with molybdenum and its compounds. Furthermore, it is imperative to establish adequate ventilation systems to effectively control the dispersion of airborne molybdenum particles, thus maintaining the air quality within permissible limits. Regular monitoring of molybdenum levels in the workplace is an essential practice, enabling the assessment of exposure risks and ensuring compliance with the sacred standards of occupational safety. In the pursuit of knowledge and enlightenment, training programs should be conducted to educate workers about the grave hazards of molybdenum exposure and the proper handling procedures that must be followed. Moreover, let us not forget the indispensable role played by regulatory bodies, whose solemn duty it is to establish permissible exposure limits (PELs) for molybdenum and diligently enforce compliance, thus safeguarding the health and safety of all workers.

Frequently Asked Questions about Molybdenum in Metal

What does molybdenum do to metal?

Molybdenum, when added to metal alloys, enhances their properties such as hardness, tensile strength, and resistance to heat and wear.

What are the attributes of molybdenum as a chemical element?

Molybdenum is a silvery-white metal with a high melting point, exceptional resistance to corrosion, and the ability to endure extreme temperatures.

How does molybdenum enhance the properties of metal alloys?

Molybdenum strengthens metal alloys, improves their resistance to corrosion, and enhances their ability to withstand high temperatures.

What are the applications of molybdenum in high-temperature environments?

Molybdenum is used in aerospace engineering, power generation, electronics, and metalworking industries due to its heat resistance and ability to endure extreme temperatures.

What is the role of molybdenum as a catalyst in metal refining and manufacturing?

Molybdenum acts as a catalyst in metal refining and manufacturing processes, enhancing the efficiency and quality of these processes.

What are the health and safety considerations of molybdenum in metal?

Molybdenum exposure can pose potential health risks, including respiratory issues, gastrointestinal disturbances, and kidney and liver damage. It is important to implement safety precautions and adhere to regulations when handling molybdenum-treated metals.