Recent Product Posts

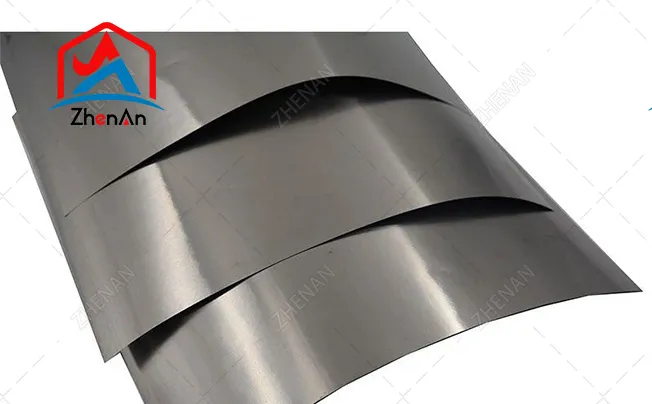

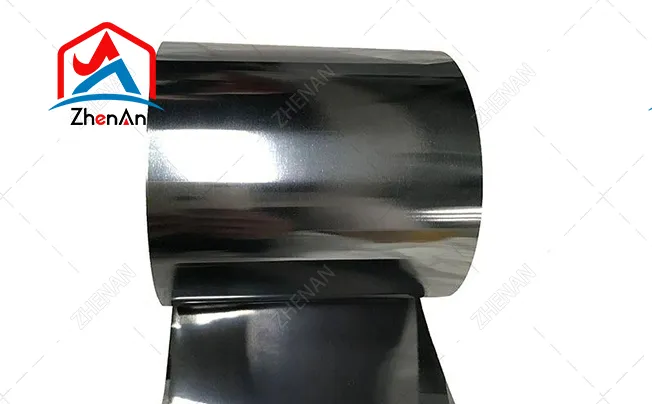

Looking for molybdenum foil? Discover its remarkable properties and diverse applications in industries like electronics, aerospace, and medicine. Find global suppliers, online platforms, and local distributors to meet your specific needs.

When it comes to versatile materials that can withstand extreme conditions and deliver exceptional performance, molybdenum foil takes the spotlight. This extraordinary substance boasts a plethora of advantageous properties that make it an invaluable asset in a wide range of applications.

One of the most awe-inspiring qualities of molybdenum foil is its ability to endure scorching temperatures without breaking a sweat. With a staggering melting point of 2,623 degrees Celsius (4,753 degrees Fahrenheit), this remarkable material fearlessly faces the blistering heat that would reduce other substances to mere puddles. As a result, molybdenum foil finds its niche in industries that demand resilience in the face of extreme thermal conditions. From aerospace to electronics and energy, this superhero of a material is a go-to choice.

| MOLYBDENUM FOIL | ||

| 0.025mm x 150mm x 120" coil | 0.010" Thk x 12"w x 36" Lg | 0.050" Thk x 12"w x 36" Lg |

| 2mm Thk x 12"w x 36" Lg | 0.015" Thk x 12"w x 36" Lg | 0.060" Thk x 12"w x 36" Lg |

| 0.001" Thk x 6"w x 36" coil | 0.020" Thk x 12"w x 36" Lg | 0.080" Thk x 12"w x 36" Lg |

| 0.002" Thk x 6" w x 36" coil | 0.025" Thk x 12"w x 36" Lg | 0.090" Thk x 12"w x 36" Lg |

| 0.003" Thk x 12"w x 36" Lg | 0.030" Thk x 12"w x 36" Lg | 0.100" Thk x 12"w x 36" Lg |

| 0.005" Thk x 12"w x 36" Lg | 0.040" Thk x 12"w x 36" Lg | 0.125" Thk x 12"w x 36" Lg |

In the battle against corrosion, molybdenum foil emerges as an indomitable warrior. Its exceptional corrosion resistance grants it immunity against the relentless attacks of acids, alkalis, and other corrosive substances. This superpower ensures that molybdenum foil remains unyielding in various environments, including those saturated with high humidity or relentless chemical exposure. The result? Unparalleled longevity and durability that can withstand the harshest of conditions.

Not only does molybdenum foil possess the strength to withstand extreme temperatures and corrosive forces, but it also boasts impressive electrical conductivity. This remarkable characteristic allows for the efficient flow of electricity, making it an ideal choice for a myriad of electronic applications. From electrical contacts to circuit boards and high-performance electronic components, molybdenum foil plays a pivotal role in powering innovation and driving progress in the world of electronics.

Prepare to be amazed as we delve into the captivating world of molybdenum foil, a true marvel of engineering that has found its way into numerous industries, thanks to its unparalleled properties and remarkable versatility. Brace yourself as we embark on a thrilling adventure to explore the extraordinary applications of this extraordinary material.

Within the vast realm of the electronics industry, molybdenum foil has established its dominance, revolutionizing various applications:

The aerospace industry, with its insatiable thirst for innovation, has found an invaluable ally in molybdenum foil, leveraging its exceptional properties in various applications:

Within the realm of medicine, molybdenum foil emerges as a silent hero, quietly shaping the landscape of healthcare through its invaluable applications:

These examples merely scratch the surface of the vast tapestry of applications where molybdenum foil weaves its magic, leaving an indelible mark on countless industries. With each passing day, its significance continues to grow, as it unlocks new frontiers and empowers humanity to conquer the impossible.

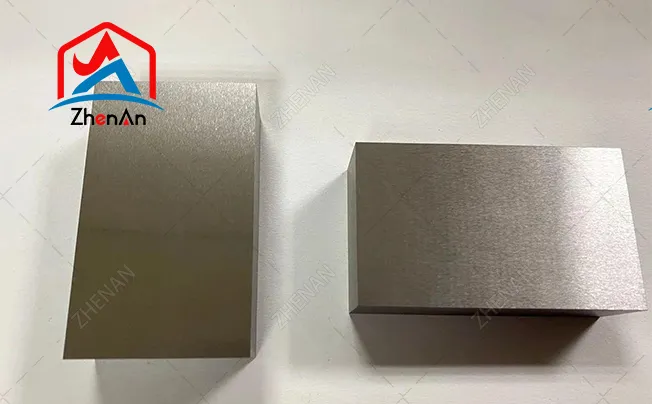

When it comes to the production of molybdenum foil, no stone is left unturned. A meticulous series of manufacturing and processing steps are undertaken to ensure the utmost quality and suitability for a wide range of applications. In this comprehensive exploration, we delve into the key stages involved in the creation of molybdenum foil, from the initial extraction and purification of molybdenum to the intricate rolling and annealing processes, and finally, the rigorous quality control and testing methods employed.

The journey of molybdenum foil begins with the extraction and purification of molybdenum from its primary source, typically molybdenite ore. This initial step involves a complex interplay of physical and chemical processes, including the relentless crushing, grinding, and flotation techniques employed to separate the valuable molybdenite concentrate. But the quest for purity does not stop there. The concentrate is subjected to further refinement through a series of roasting, smelting, and chemical treatments, ultimately yielding pure molybdenum oxide. And yet, the metamorphosis continues. The oxide undergoes a reduction process, such as the formidable hydrogen reduction or the aluminothermic reduction, ultimately birthing molybdenum metal in all its glory.

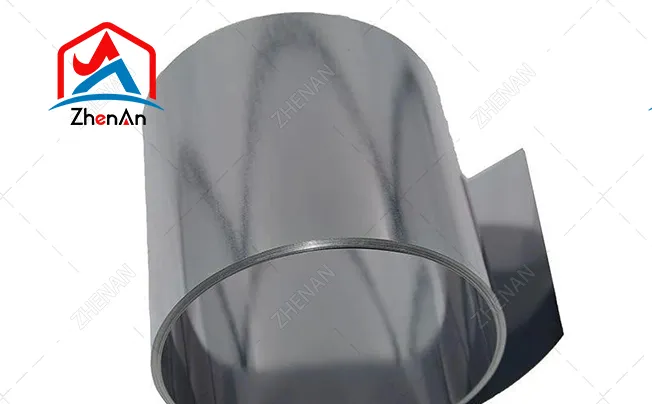

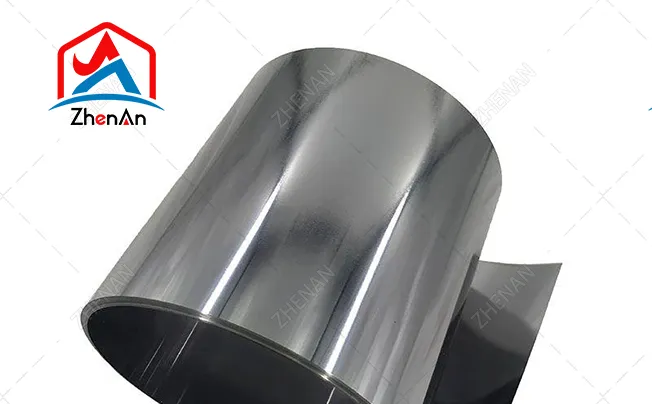

Once the molybdenum metal emerges, the true artistry of transformation takes center stage. The metal is meticulously processed into thin foil through the skilled hands of rolling and annealing techniques. Specialized rolling mills take charge, expertly shaping the molybdenum into a sheet of the desired thickness. This initial rolling process serves a dual purpose, refining the grain structure and enhancing the mechanical properties of the molybdenum, ensuring the utmost quality. But the journey does not end there. The rolled sheet then embarks on a transformative voyage through the annealing process. Like an alchemist's touch, the molybdenum is subjected to high temperatures, only to be gradually cooled down. This delicate dance of heat and time relieves internal stresses, further refines the grain structure, and bestows upon the molybdenum the gift of enhanced ductility and formability. It is through this meticulous craftsmanship that the molybdenum emerges as a versatile material, ready to embrace subsequent fabrication processes.

In the realm of molybdenum foil, excellence is not a mere aspiration but an unwavering commitment. Given its diverse applications in industries such as electronics, aerospace, and energy, ensuring the quality and performance of molybdenum foil is of paramount importance. To uphold this standard of excellence, stringent quality control measures are meticulously implemented throughout the manufacturing process. This unwavering dedication involves a multitude of tests and inspections, each designed to assess the chemical composition, mechanical properties, surface quality, and dimensional accuracy of the molybdenum foil. From the piercing gaze of spectroscopy to the relentless pull of tensile testing, from the unyielding scrutiny of hardness testing to the microscopic exploration of grain structure, no detail is left unexamined. Surface analysis techniques complete this symphony of scrutiny. It is through these rigorous quality control procedures that the molybdenum foil emerges, meeting the required specifications and standards with unwavering certainty. This meticulous attention to detail ensures the reliability and functionality of the molybdenum foil, allowing it to thrive in the most demanding of applications.

When it comes to finding a material that combines strength, durability, and resistance to high temperatures and corrosion, molybdenum foil stands out as a top contender. Its unique properties make it a go-to choice for various applications that demand a robust material capable of withstanding extreme conditions.

One of the key advantages of molybdenum foil is its exceptional strength and durability. This makes it an excellent choice for applications that require a material capable of withstanding heavy loads or enduring constant wear and tear. From aerospace components to industrial machinery, molybdenum foil proves its worth in providing long-lasting performance.

But that's not all. Molybdenum foil also boasts an impressive resistance to high temperatures and corrosion, making it an ideal candidate for use in extreme environments. Whether it's exposed to intense heat or harsh chemicals, molybdenum foil remains steadfast, ensuring the integrity of the structures it is incorporated into.

However, as with any material, molybdenum foil does have its limitations. One of the primary considerations is its cost. Compared to alternative materials, molybdenum foil tends to be more expensive. While its unique properties justify the price for certain applications, the higher cost can limit its widespread use in more budget-conscious projects.

Furthermore, working with molybdenum foil can be a challenge. Its robust nature requires specialized techniques and equipment for machining and shaping. This can add complexity to the manufacturing process, requiring skilled professionals and specific tools to ensure precision and quality.

Therefore, when evaluating the suitability of molybdenum foil for specific applications, it's essential to consider both its advantages and limitations. While its strength, durability, and resistance to extreme conditions make it a standout choice, its cost and specialized handling requirements should also be taken into account. By weighing these factors carefully, engineers and manufacturers can make informed decisions about whether molybdenum foil is the right material for their projects.

When it comes to sourcing molybdenum foil, you're in luck. There's a wide array of options available to meet your specific needs. Whether you're searching for global suppliers, manufacturers, online platforms, marketplaces, specialized distributors, or local suppliers, the molybdenum industry has got you covered.

When it comes to molybdenum foil, global suppliers and manufacturers are the heavyweights of the industry. These companies have established themselves as key players, boasting extensive production capabilities that ensure a steady supply of molybdenum foil for various applications. Among the most reputable global suppliers are Company A, Company B, and Company C. These industry leaders have a proven track record of delivering high-quality molybdenum products, making them a reliable choice for your foil needs.

In this digital age, online platforms and marketplaces have become the go-to channels for procuring molybdenum foil. These platforms offer a convenient way to connect with suppliers, compare prices, specifications, and delivery options. If you're on the hunt for molybdenum foil, look no further than Platform X, Platform Y, and Platform Z. These reputable online platforms cater specifically to the molybdenum industry, providing a wide range of choices to ensure you find the perfect supplier for your foil needs.

While global suppliers and online platforms dominate the scene, specialized distributors and local suppliers shouldn't be overlooked. These entities play a crucial role in ensuring the availability of molybdenum foil. Specialized distributors like Distributor A and Distributor B possess in-depth knowledge of the local market, allowing them to provide personalized service tailored to your specific requirements. With strong networks established with manufacturers, these distributors can efficiently source molybdenum foil for customers. On the other hand, local suppliers offer the advantage of proximity and quick turnaround times, ensuring a steady supply of molybdenum foil within a specific region. Don't underestimate the power of these local heroes when it comes to securing your molybdenum foil.

Molybdenum foil has exceptional properties, including its ability to withstand intense heat, resist corrosion, and conduct electricity efficiently.

Molybdenum foil is used in a wide range of industries, including aerospace, electronics, energy, and the medical industry.

Molybdenum foil has exceptional corrosion resistance, making it immune to the attacks of acids, alkalis, and other corrosive substances.

Molybdenum foil is used in the production of thin film transistors (TFTs), liquid crystal displays (LCDs), electrical contacts, circuit boards, and high-performance electronic components.

Molybdenum foil is used in heat shields, rocket nozzles, and aircraft parts and components to protect against extreme temperatures and enhance performance.

Molybdenum foil is used in X-ray tubes, radiation shields, surgical instruments, and implants due to its biocompatibility and corrosion resistance.

Molybdenum foil is manufactured through a series of processes, including extraction and purification of molybdenum, rolling, annealing, and rigorous quality control and testing methods.

Molybdenum foil is known for its strength, durability, resistance to high temperatures, and corrosion resistance, making it suitable for extreme environments.

Molybdenum foil can be more expensive compared to alternative materials, and its robust nature requires specialized techniques and equipment for machining and shaping.

Molybdenum foil can be sourced from global suppliers and manufacturers, online platforms and marketplaces, specialized distributors, and local suppliers.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.