Recent Product Posts

Discover the Power of Moly Foil: Unleashing the Potential of Molybdenum. Harness the high-performance and versatility of moly foil in various industries.

When it comes to high-performance materials, one name stands out: molybdenum. And at the heart of this extraordinary metal lies moly foil, a thin sheet that is revolutionizing industries across the globe. Strap in and prepare to dive deep into the fascinating world of moly foil.

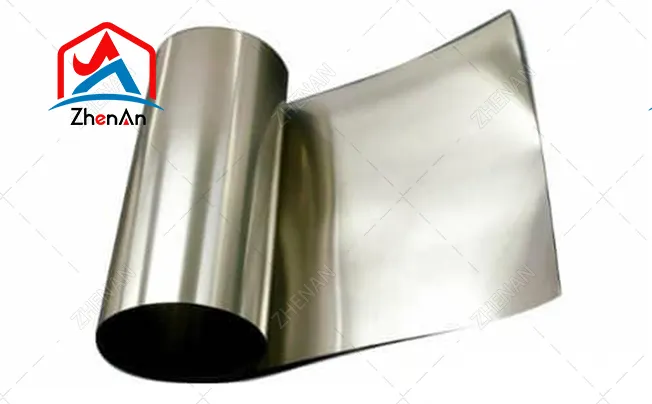

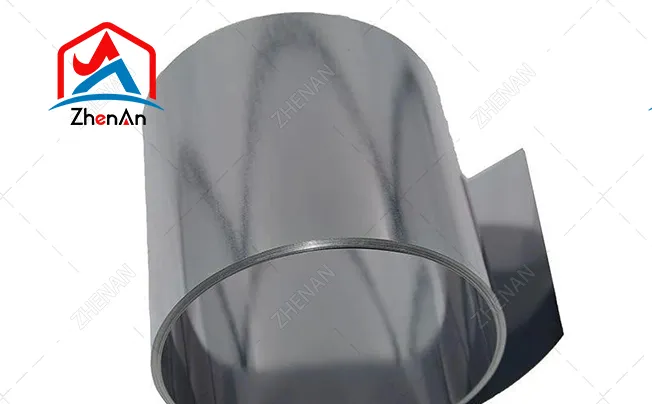

Moly foil, also known as molybdenum foil, is a marvel of modern engineering. Crafted from pure molybdenum, it boasts a purity level of 99.95% or higher, ensuring unparalleled performance and reliability. This refractory metal is renowned for its ability to withstand scorching temperatures and retain its strength even in the most demanding environments.

But what sets moly foil apart from the competition? Its secret lies in the meticulous process of rolling, where molybdenum is compressed and flattened into thin, flexible sheets. This technique not only enhances its thermal and electrical conductivity but also allows for a wide range of applications across various industries.

| item | value |

| Place of Origin | China |

| Brand Name | ZhenAn |

| Model Number | 0.3-50mm |

| Dimensions | customize |

| Product name | Molybdenum Sheet |

| Surface | Polished Molybdenum Sheet |

| Shape | Square |

| Material | Molybednum |

| Purity | Mo 99.95% |

| Color | Sliver Gray |

| Density | 10.2g/cm3 |

| Keywords | High Purity Molybdenum Sheet |

| Size | Customer's Requiry |

The applications and uses of moly foil are as diverse as the industries it serves. In the world of electronics, this exceptional material takes center stage as a substrate for thin-film transistors, integrated circuits, and semiconductor devices. Its high thermal conductivity and low coefficient of thermal expansion make it an ideal choice for heat sinks, heat shields, and thermal management components.

But the wonders of moly foil don't stop there. In the aerospace and defense sectors, where extreme temperatures and corrosive environments reign supreme, moly foil rises to the challenge. Its ability to withstand these harsh conditions makes it an invaluable asset in aircraft components, missile systems, and spacecraft technology.

Looking beyond the skies, moly foil finds its place in industrial settings as well. Furnace elements, electrical contacts, and sintering boats all benefit from the exceptional properties of this remarkable material. And let's not forget its role as a catalyst support in chemical reactions, where it enables groundbreaking advancements in various scientific fields.

Are you ready to harness the power of moly foil? Whether you're in the electronics, aerospace, or industrial sector, this extraordinary material is poised to elevate your projects to new heights. With its high melting point, excellent thermal and electrical conductivity, and unmatched versatility, moly foil is a game-changer.

So, what are you waiting for? Embrace the power of molybdenum and unlock a world of possibilities with moly foil. Your journey towards innovation starts now.

Molybdenum foil, affectionately known as moly foil, stands as a highly sought-after material in numerous industries due to its exceptional properties. Its outstanding features contribute to its widespread use in applications where high performance and unwavering reliability are paramount.

One of the most remarkable qualities of moly foil lies in its ability to endure extreme temperatures. With a melting point reaching a scorching 2,623 degrees Celsius (4,753 degrees Fahrenheit), molybdenum can withstand intense heat without compromising its structural integrity. This unique attribute makes it the perfect candidate for applications that involve blistering temperatures.

Not only can moly foil handle extreme temperatures, but it also exhibits excellent thermal conductivity. This means it excels at efficiently transferring heat in various thermal management systems. By facilitating the seamless flow of heat, molybdenum foil ensures optimal performance and prevents any potential overheating issues.

One of the standout advantages of molybdenum foil is its unparalleled resistance to corrosion. It can withstand even the harshest environments, including exposure to corrosive gases and liquids, without succumbing to deterioration. This exceptional corrosion resistance makes moly foil an exceptional choice for applications in industries such as chemical, petrochemical, and pharmaceutical, where exposure to corrosive substances is a common occurrence.

When it comes to demanding applications, molybdenum foil truly shines. Its remarkable strength and durability allow it to thrive in high-stress environments. With its high tensile strength, moly foil can withstand significant mechanical stress without deformation or failure. Additionally, its excellent resistance to fatigue ensures long-term performance and unwavering reliability in critical applications.

Overall, the unique combination of a high melting point, exceptional thermal conductivity, resistance to corrosion, and remarkable strength and durability make molybdenum foil an advantageous material for a wide range of industries and applications.

When it comes to versatility and application diversity, few materials can rival the power of molybdenum foil, affectionately known as Moly foil. In the realms of electronics, aerospace, and energy, this remarkable substance reigns supreme. However, harnessing the true potential of Moly foil requires more than a basic understanding; it demands a comprehensive grasp of the intricate nuances surrounding its preparation, handling, cutting, shaping, storage, and maintenance. In this definitive guide, we unveil the secrets to unlocking the optimal performance and longevity of Moly foil, empowering you to wield its power with finesse.

Before embarking on your Moly foil journey, it is paramount to lay a solid foundation through meticulous preparation and expert handling techniques. The importance of cleanliness cannot be overstated. To safeguard against damage or contamination, donning gloves becomes an essential ritual, ensuring that no oils or contaminants find their way onto the foil's pristine surface. Furthermore, storing Moly foil in a clean and dry environment is a wise choice, preserving its integrity and shielding it from potential harm.

To achieve mastery over Moly foil, one must embrace the art of precision cutting and shaping. Depending on your desired outcome, a plethora of techniques, including laser cutting, shearing, or punching, await your exploration. However, the key lies in selecting the appropriate cutting tool and ensuring its blades remain razor-sharp. Only then can you achieve the pinnacle of clean and accurate cuts. When it comes to shaping, a gentle touch is paramount. Bending or rolling must be executed with utmost care to evade the perils of cracking or damaging the foil, preserving its structural integrity.

Like any prized possession, Moly foil demands meticulous storage and maintenance rituals to safeguard its longevity and uphold its unparalleled quality. A controlled and dry environment serves as its sanctuary, shielding it from the ravages of direct sunlight and extreme temperatures. To further fortify its defense, preserving the foil's original packaging or utilizing protective coverings becomes a non-negotiable mandate, thwarting any attempts by scratches or surface damage to mar its brilliance. Regular inspections and gentle cleaning with non-abrasive materials serve as the final touch, ensuring the removal of any contaminants or debris that may impede the foil's exceptional performance.

When it comes to selecting molybdenum (moly) foil for your specific applications, there are several crucial factors that you need to take into consideration. These factors go beyond just the basic properties of the foil and delve into the intricate details that can make or break the success of your project. In this article, we will explore these key factors in depth, providing you with the knowledge you need to make an informed decision.

One of the first factors that you need to carefully consider is the thickness and dimensions of the moly foil. This is not a one-size-fits-all scenario. The thickness of the foil plays a significant role in determining its strength, durability, and suitability for different processes. You need to assess the specific requirements of your application and choose a foil thickness that aligns with those needs. Additionally, the dimensions of the foil, such as its width and length, should be in line with the specifications of your project. By meticulously evaluating these factors, you can ensure that the moly foil you select will perform optimally and meet your desired specifications.

Another vital aspect to consider when choosing moly foil is its purity and adherence to quality standards. Molybdenum is available in various purities, ranging from standard-grade to high-purity options. The level of purity required depends on the specific application and the desired properties of the foil. For instance, if you are working on a project that demands exceptional corrosion resistance or high-temperature performance, opting for a higher purity moly foil might be necessary. It is crucial to verify that the moly foil you choose meets industry standards and certifications, ensuring its reliability, performance, and compatibility with your intended use. By digging deeper into the purity and quality standards, you can be confident that your chosen moly foil will deliver the desired results.

While the properties of the moly foil are undoubtedly important, the reputation and certifications of the supplier should not be overlooked. Choosing a reliable and reputable supplier is paramount to obtaining moly foil that meets your required specifications. A supplier with a track record of delivering high-quality products demonstrates their commitment to excellence. Furthermore, certifications such as ISO or industry-specific accreditations provide an added layer of assurance, indicating that the supplier adheres to recognized standards. Thoroughly researching and selecting a reputable supplier will help ensure the reliability and consistency of the moly foil you purchase. By building trust and confidence in your supplier, you can rest easy knowing that you are making a wise investment.

When it comes to molybdenum foil, curious minds want to know more. In this comprehensive guide, we'll dive deep into the world of moly foil, exploring its applications, advantages, and alternatives. Whether you're a seasoned industry professional or a curious beginner, this guide will provide the answers you seek.

If you're looking for a material that can handle scorching temperatures, molybdenum foil is your go-to choice. With a mind-boggling melting point of 2,623 degrees Celsius, this remarkable material remains unfazed even in the most extreme heat environments. Whether it's furnace heating elements, sintering boats, or aerospace components, molybdenum foil has got you covered.

The electrical and electronic industries have found a steadfast ally in molybdenum foil. Thanks to its exceptional electrical conductivity and low coefficient of thermal expansion, moly foil is the preferred material for power semiconductor devices, thin-film transistors, and even as a back contact material in solar cells. Its ability to endure high temperatures and resist corrosion only adds to its allure in these industries.

While molybdenum foil reigns supreme in many applications, it's always good to have alternatives up your sleeve. Tungsten foil, for example, shares similar high-temperature properties and often serves as a worthy substitute. Additionally, tantalum and niobium foils can be considered for specific applications. The key lies in evaluating the unique needs and constraints of your project to determine the perfect alternative to molybdenum foil.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.