Recent Product Posts

Learn about molybdenum's common uses across industries, including steel production, catalysts, electrical contacts, glass manufacturing and aerospace applications.

Molybdenum, a versatile and highly valuable element, finds extensive use in various industrial applications. Its unique properties make it an essential component in numerous sectors, contributing to advancements in technology, manufacturing, and defense.

Molybdenum plays a crucial role in the production of steel alloys, enhancing their strength, hardness, and resistance to corrosion. By adding small amounts of molybdenum to steel, it becomes more durable and better suited for demanding applications such as construction, automotive, and machinery manufacturing. The alloy's ability to withstand high temperatures and extreme conditions makes it invaluable in the production of structural components and tools.

|

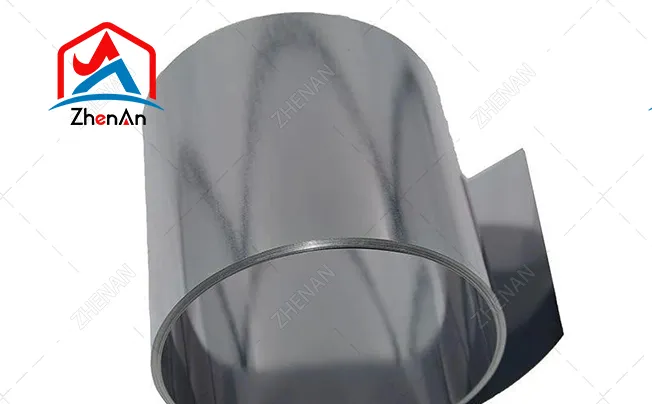

Thickness mm

|

Width mm

|

Length mm

|

|

0.05 ~ 0.10

|

150

|

L

|

|

0.10 ~ 0.15

|

300

|

1000

|

|

0.15 ~ 0.20

|

400

|

1500

|

|

0.20 ~ 0.30

|

650

|

2540

|

|

0.30 ~ 0.50

|

750

|

3000

|

|

0.50 ~ 1.0

|

750

|

5000

|

|

1.0 ~ 2.0

|

600

|

5000

|

|

2.0 ~ 3.0

|

600

|

3000

|

|

> 3.0

|

600

|

L

|

Molybdenum-based catalysts are widely used in the petroleum industry to facilitate essential chemical reactions during the refining process. These catalysts help break down complex hydrocarbons into simpler compounds, improving the efficiency and yield of petroleum products. Molybdenum's catalytic properties enable the production of cleaner fuels, such as gasoline and diesel, by reducing harmful emissions and enhancing the overall quality of the end products.

Molybdenum's excellent electrical conductivity and high melting point make it an ideal material for manufacturing electrical contacts and filaments. It is commonly used in electrical devices, such as switches, relays, and light bulbs, where reliable and efficient electrical conductivity is essential. Molybdenum filaments are also extensively utilized in the production of incandescent lamps, providing a durable and stable heat source that emits bright light.

Molybdenum is employed as an additive in the production of glass and ceramics, imparting desirable properties to these materials. It enhances the strength and durability of glass, making it suitable for applications that require resistance to thermal stress and mechanical strain. In ceramics, molybdenum improves the material's ability to withstand high temperatures and provides excellent corrosion resistance, making it valuable for manufacturing crucibles, furnace parts, and other heat-resistant components.

Molybdenum coatings are widely used in aerospace and defense applications due to their exceptional properties. These coatings offer superior protection against corrosion, wear, and high temperatures, making them ideal for aircraft components, missile systems, and military equipment. Molybdenum-coated surfaces also exhibit low friction properties, reducing drag and improving fuel efficiency in aerospace applications. Additionally, molybdenum's high thermal conductivity makes it valuable for heat dissipation in electronic devices used in defense systems.

Molybdenum, an essential trace element for humans and animals, plays a crucial role in various enzymatic functions within the body. Its presence is vital for the proper functioning of enzymes that are involved in important metabolic processes. Molybdenum also finds application in the treatment of copper toxicity, where it helps to reduce the levels of excess copper in the body. Additionally, this mineral contributes to the prevention of certain types of anemia by aiding in the production of red blood cells. Moreover, ongoing research suggests that molybdenum may possess potential anti-cancer properties, making it an intriguing area of study in the field of oncology.

What are 5 common uses for molybdenum, you may ask? Well, beyond its medical applications, molybdenum has a range of uses in various industries. One common use is in the production of stainless steel, where it is added to enhance the corrosion resistance and strength of the alloy. Molybdenum is also utilized in the manufacturing of aircraft parts, such as turbine blades and structural components, due to its high melting point and excellent heat resistance.

Furthermore, molybdenum is employed in the production of electrical contacts and electrodes, thanks to its ability to withstand high temperatures and resist corrosion. Its use in these applications ensures reliable and efficient electrical conductivity. Additionally, molybdenum is utilized in the production of catalysts, which are substances that speed up chemical reactions without being consumed in the process. These catalysts find application in various industrial processes, such as petroleum refining and the production of chemicals.

Lastly, molybdenum is used in the production of glass, where it acts as a coloring agent to create a variety of shades and hues. Its ability to withstand high temperatures makes it suitable for use in glass manufacturing processes.

Molybdenum, a versatile transition metal, plays a crucial role in various applications related to energy and the environment. Its unique properties make it indispensable in renewable energy technologies, acting as a catalyst in the production of biofuels, facilitating the removal of sulfur from fossil fuels, contributing to water treatment applications, and aiding in the reduction of greenhouse gas emissions. Such is the significance of molybdenum in addressing environmental challenges.

Molybdenum finds extensive use in renewable energy technologies due to its exceptional strength, high melting point, and excellent corrosion resistance. It is a vital component in the production of solar cells, where it acts as a conductive back contact and facilitates the efficient conversion of sunlight into electricity. The brilliance of molybdenum shines in wind turbines as well, enhancing their structural integrity and overall performance. Furthermore, this versatile metal is employed in the manufacturing of rechargeable batteries, enabling the storage and utilization of clean energy.

Molybdenum serves as a catalyst in the production of biofuels, such as biodiesel and bioethanol. Through various chemical processes, molybdenum compounds aid in breaking down organic materials, such as vegetable oils or biomass, into their constituent components, which can then be further processed into biofuels. This catalytic role of molybdenum helps to enhance the efficiency and sustainability of biofuel production, contributing to the transition towards cleaner and renewable energy sources.

Molybdenum-based catalysts play a crucial role in the removal of sulfur from fossil fuels, particularly in the petroleum industry. Sulfur compounds present in crude oil and other fossil fuel sources can have detrimental effects on the environment and human health when released during combustion. Molybdenum catalysts aid in converting sulfur-containing compounds into less harmful substances, thereby reducing the emission of sulfur dioxide and other pollutants into the atmosphere. This process helps to mitigate air pollution and improve the overall quality of fossil fuel-derived energy.

Molybdenum compounds are utilized in various water treatment applications, including the removal of contaminants and the prevention of bacterial growth. Molybdenum-based catalysts and adsorbents are effective in removing heavy metals, such as arsenic and lead, from water sources, ensuring the safety and purity of drinking water. Additionally, molybdenum-containing compounds are employed in wastewater treatment processes to break down organic pollutants and promote the degradation of harmful substances, thus minimizing the environmental impact of industrial effluents.

Molybdenum plays a significant role in reducing greenhouse gas emissions, primarily through its involvement in catalytic converters utilized in vehicle exhaust systems. These converters contain molybdenum-based catalysts that facilitate the conversion of harmful gases, such as nitrogen oxides and carbon monoxide, into less harmful compounds. By promoting these chemical reactions, molybdenum helps to minimize the release of pollutants into the atmosphere, contributing to the mitigation of climate change and the preservation of air quality.

Molybdenum, a versatile transition metal, finds extensive use in various applications within the electronics and technology sectors. Its unique properties make it an ideal choice for high-temperature applications, the semiconductor industry, thin film deposition for electronic components, electrodes in electronic devices, and enhancing the performance of electronic circuits.

Molybdenum's exceptional ability to withstand high temperatures makes it invaluable in various high-temperature applications. It is commonly used in electric furnaces, heating elements, and as a structural material in aerospace and defense industries. Its high melting point, low coefficient of thermal expansion, and excellent thermal conductivity make it an ideal choice for such demanding environments.

Molybdenum plays a vital role in the semiconductor industry, particularly in the production of integrated circuits and transistors. It is used as a contact material, providing a reliable and low-resistance connection between the semiconductor device and external circuitry. Molybdenum's high electrical conductivity and compatibility with silicon make it an essential component in the manufacturing of advanced electronics.

Molybdenum is widely utilized in thin film deposition processes, which are crucial for the fabrication of electronic components. It is commonly used as a barrier layer in thin film technology, preventing diffusion between different layers and enhancing the adhesion of subsequent layers. The use of molybdenum in thin film deposition ensures the creation of reliable and high-performance electronic devices.

Molybdenum is extensively employed as electrodes in various electronic devices, including flat-panel displays, photovoltaic cells, and vacuum tubes. Its high electrical conductivity, low thermal expansion, and resistance to corrosion make it an excellent choice for these applications. Molybdenum electrodes ensure efficient energy transfer, enabling the proper functioning of electronic devices.

Molybdenum's unique properties also contribute to enhancing the performance of electronic circuits. It is used as an alloying element in certain types of steel used for circuit boards, improving their strength and thermal stability. Additionally, molybdenum is utilized in the production of high-speed integrated circuits, where its ability to reduce resistance and capacitance enables faster signal transmission and improved overall circuit performance.

Molybdenum, with its versatile properties, finds extensive use in various applications within the electronics and technology sectors. Five common uses for molybdenum include:

Molybdenum, a most versatile element, finds itself in various applications across different industries due to its unique and exceptional properties. Apart from its well-known uses in steel alloys and catalysts, molybdenum also serves several other purposes, which are worth exploring in greater detail.

One of the lesser-known uses of molybdenum lies in its application as a pigment in the production of paints and dyes. Compounds such as molybdate and chromate, derived from molybdenum, possess the remarkable ability to provide vibrant colors and excellent lightfastness. This makes them highly sought after in the automotive, construction, and textile industries, where the demand for long-lasting and visually appealing finishes is paramount.

Due to its notably high melting point and low friction coefficient, molybdenum has found its way into the realm of lubricant additives. By incorporating molybdenum into lubricants, the wear and tear experienced by machinery can be significantly reduced, thereby improving their overall performance and longevity. Among the various forms of molybdenum utilized in this capacity, molybdenum disulfide stands out as a widely employed dry lubricant in applications ranging from automotive engines to industrial machinery.

Molybdenum assumes a crucial role as an alloying agent in the production of superalloys, which are materials highly esteemed for their exceptional performance in extreme environments. Industries such as aerospace and power generation heavily rely on these high-performance materials, and the addition of molybdenum to the alloying process contributes significantly to their strength, heat resistance, and corrosion resistance. As a result, superalloys fortified with molybdenum prove themselves invaluable in demanding applications that require materials capable of withstanding the harshest conditions.

With its exceptional ability to withstand high temperatures and resist corrosion, molybdenum has found extensive use in the realm of nuclear energy applications. Within the construction of reactor cores, fuel rods, and various other components of nuclear reactors, molybdenum ensures the safe and efficient generation of nuclear power. Its remarkable properties make it an indispensable material, providing the necessary strength and durability needed to withstand the rigorous demands of the nuclear industry.

Derived from molybdenum, the compound known as molybdenum disulfide has garnered widespread recognition as an exceptional dry lubricant. Its ability to form a thin, solid film enables it to reduce friction and wear in a wide range of mechanical systems. From the intricate mechanisms of precision instruments to the powerful engines of automobiles, molybdenum disulfide ensures the smooth operation and extended lifespan of these vital machines.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.