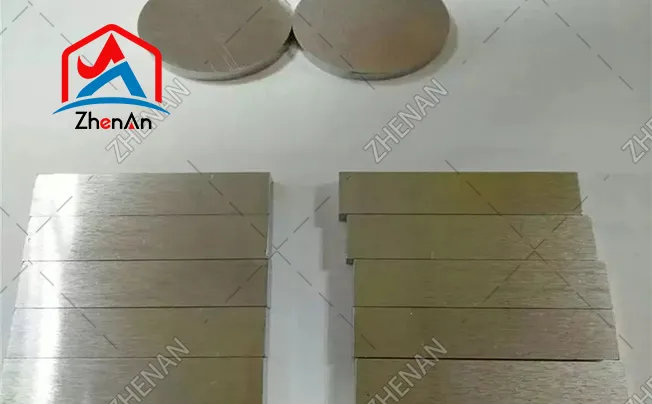

The main difference between TZM and TZC is the content of doping elements, that is, the total content of carbon, zirconium, and titanium in the TZM alloy is 0.71%, while the total content of carbon, zirconium, and titanium in TZC in molybdenum is 2.2% higher than that of TZM. In addition, the impurity content is also higher than that of TZM. However, they are based on molybdenum alloys.

The main components of TZM alloy are 0.50% titanium, 0.08% zirconium and 0.02% carbon. TZM alloy has e,xcellent properties such as high melting point, high strength, high elastic modulus, small linear expansion coefficient, low vapor pressure, good thermal conductivity, strong corrosion resistance, and good high-temperature mechanical properties, so it can be widely used in many fields.

The composition of TZC alloy (titanium zirconium carbon alloy) is as follows: 1.2% titanium, 0.3% zirconium, 0.1% carbon. It has excellent high temperature strength, high rehigh-temperaturetemperature and good room temperature plastic,ity. It is often produced using powder metallurgy and vacuum arc melting production methods.