Recent Product Posts

An iron alloy whose main components are tungsten and iron. It also contains impurities such as manganese, silicon, carbon, phosphorus, sulfur, copper, and tin. Used as alloy additive in steelmaking. Commonly used ferrotungsten contains 70% and 80% tungsten. Ferrotungsten is produced from tungsten manganese ore by reducing it with carbon in an electric furnace. Mainly used as alloying element additive for tungsten-containing alloy steel (such as high-speed steel).

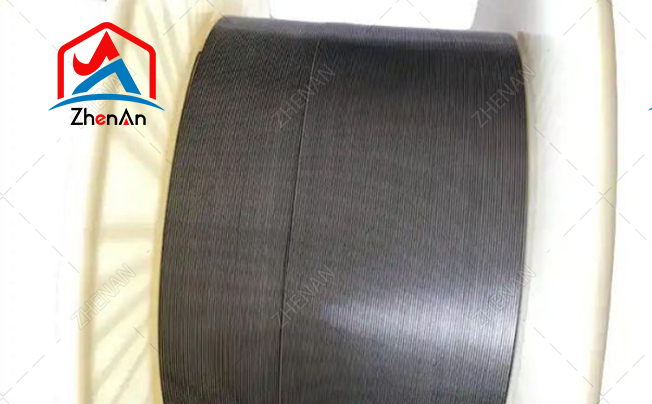

Ferrotungsten Parameters

| Grade | Chemical composition % | |||||||||||

| W | C | P | S | SI | MN | CU | AS | BI | PB | SB | SN | |

| ≥ | < | |||||||||||

| FeW70 | 70 | 0.8 | 0.06 | 0.1 | 1 | 0.6 | 0.18 | 0.1 | 0.05 | 0.1 | — | — |

| FeW80-A | 75.0-85.0 | 0.1 | 0.03 | 0.06 | 0.5 | 0.25 | 0.1 | 0.06 | 0.05 | 0.05 | 0.05 | 0.06 |

| FeW80-B | 75.0-85.0 | 0.3 | 0.04 | 0.07 | 0.7 | 0.35 | 0.12 | 0.08 | — | — | 0.05 | 0.08 |

| FeW80-C | 75.0-85.0 | 0.4 | 0.05 | 0.08 | 0.7 | 0.5 | 0.15 | 0.1 | — | — | 0.05 | 0.08 |

| Ferro Tungsten 80 And Ferro Tungsten 70 For Sale | ||||||||||||

| Usage: Steelmaking Additive | ||||||||||||

| Application: Used In the Production Of High-Speed Steel Such As Turbine Blades, aircraft, Heat Sinks Etc. | ||||||||||||

| Size:3–50mm | ||||||||||||

| Packing: 100Kgs Drum | ||||||||||||

| Melting Point: >1800°C | ||||||||||||

Ferrotungsten classification

An iron alloy whose main components are tungsten and iron. It also contains manganese, silicon, carbon, phosphorus, sulfur, copper, tin and other impurities, and is an alloying agent used in steelmaking. According to the different tungsten content, ferrotungsten is divided into: FeW75 (containing W70%~80%, C≤0.20%, P≤0.04%, S≤0.08%, Si≤0.5%, Mn≤0.25%) and FeW80 (containing W75 .0%~85.0%, C≤0.20%, P≤O.04%, S≤0.08%, Si≤0.7%, Mn≤0.25%).

Properties and uses of ferrotungsten

Tungsten is a silver-gray metal. The atomic weight is 183.85. Electronic structure 4f145d46s2. Density (20℃) 19.3g/cm3. Melting point 3400℃. Boiling point 5555℃. Tungsten forms solid solutions with iron and two intermetallic compounds Fe2W and Fe3W2 or Fe7W6, but they are unstable at high temperatures. The melting temperature of ferrotungsten containing 75%~85% W is higher than 2500°C, so it cannot be released from the furnace and can only be produced by the accumulation method or the iron extraction method. The density of industrial ferrotungsten is about 15.3g/cm3.

Application areas of ferrotungsten

Ferrotungsten is used as an additive to tungsten in steelmaking and casting. Tungsten is one of the most important alloying elements in the production of special steels. Tungsten can not only reduce the elongation of steel to a small extent, but also increase the strength limit and yield point of steel. It can also improve the hardness and wear resistance of steel. Of particular importance is the good influence tungsten has on the high-temperature mechanical properties of steel, improving heat resistance and tempering stability.

Company Advantage

Unparalleled expertise: With thirty years of practical experience we have an unparalleled understanding of the metalworking process, ensuring top quality in all our products.

Extensive product range: Our diverse product portfolio caters to various industrial needs, making us a one-stop solution for every metallurgical requirement

Quality Assurance: We implement strict quality control measures at every stage of production to ensure our products meet or exceed industry standards.

Customization: We understand that each customer's needs are unique. Our flexible production capabilities allow us to customize products to specific requirements

Global influence: With an extensive international trade network and experience, we promote the Wufeng import and export business, covering customers around the world.

Commitment to Sustainability: We attach great importance to sustainable practices in our production processes and strive to minimize our impact on the environment.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.