What is molybdenum?

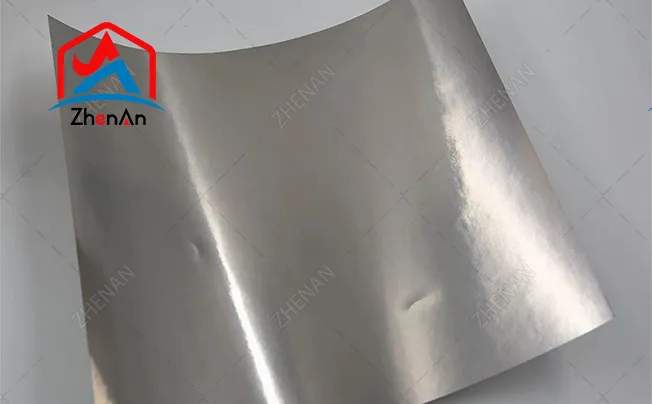

Molybdenum, dear reader, is a chemical element of great significance. With the symbol Mo and atomic number 42, it graces the periodic table as a silvery-white metal, belonging to the esteemed group of transition metals. Its remarkable properties, including a high melting point and exceptional durability, render it suitable for a myriad of applications. This precious element is primarily extracted from molybdenite, a mineral that boasts the presence of molybdenum sulfide. It is not uncommon to find this element in combination with other elements, nestled within minerals and ores.

Definition and characteristics of molybdenum

Allow me to expound upon the definition and characteristics of molybdenum, for it is a matter of great interest. Classified as a refractory metal, it possesses a melting point that soars to 2,623 degrees Celsius (4,753 degrees Fahrenheit). Such a feat is truly remarkable, wouldn't you agree? Furthermore, its density of 10.28 grams per cubic centimeter bestows upon it a weightiness that sets it apart. Yet, despite its heaviness, molybdenum boasts excellent thermal and electrical conductivity, coupled with a low coefficient of thermal expansion. Such a combination is a testament to its exceptional nature. Moreover, it remains resolute in the face of corrosion, refusing to react with hydrochloric acid or sulfuric acid at room temperature.

Common uses of molybdenum

Now, let us delve into the common uses of molybdenum, for they are as diverse as they are noteworthy. Its presence is felt prominently in various industries, leaving an indelible mark. In the production of stainless steel, molybdenum plays a vital role, enhancing the steel's resistance to corrosion and fortifying its strength at elevated temperatures. A truly indispensable contribution, wouldn't you say? Moreover, this remarkable metal finds its way into the manufacturing of superalloys, those marvels of engineering that power jet engines and gas turbines. What a testament to its versatility! In the petroleum industry, molybdenum takes on the role of a catalyst, aiding in the removal of sulfur from fuels. Such a noble endeavor, dear reader. But wait, there is more! Molybdenum also graces us with its presence in electrical contacts, filaments, and even as a lubricant additive. And let us not forget molybdenum disulfide, derived from this extraordinary element, which serves as a dry lubricant in high-friction environments. Truly, the applications of molybdenum are as boundless as the imagination itself.

Can molybdenum remove heavy metals?

Indeed, the question of whether molybdenum possesses the ability to remove heavy metals is one that has garnered much attention in recent scientific discourse. Molybdenum, a trace element that can be found in the very fabric of our soil, plants, and animals, is believed to play a crucial role in the extraction of heavy metals from a variety of environmental sources. Its remarkable capacity to bind with heavy metals, including the likes of lead, cadmium, and arsenic, allows for their expulsion from water, soil, and even the depths of industrial waste. It is through this extraordinary affinity that molybdenum acts as a catalyst, facilitating a plethora of enzymatic reactions that are instrumental in the detoxification and elimination of heavy metals from the human body.

Understanding the role of molybdenum in heavy metal removal

At the heart of molybdenum's prowess in heavy metal removal lies its primary function - its involvement in the production of enzymes that possess the remarkable ability to break down and convert toxic heavy metals into forms that are considerably less harmful. These enzymes, known to the learned few as molybdoenzymes, are nothing short of indispensable when it comes to the body's natural defense mechanisms against the perils of heavy metal toxicity. Moreover, molybdenum, in its benevolence, goes beyond its catalytic role and enhances the efficiency of other vital detoxification pathways within the human body, such as the synthesis of glutathione. This harmonious interplay of molybdenum and various detoxification mechanisms serves to further fortify the body's resolve in liberating itself from the clutches of heavy metal contamination.

Research and studies on molybdenum's effectiveness in removing heavy metals

Throughout the annals of scientific inquiry, numerous studies have been undertaken to ascertain the true effectiveness of molybdenum in its valiant quest to rid the world of heavy metals. These scholarly endeavors have yielded promising results, with evidence suggesting that the supplementation of molybdenum can indeed bolster the body's natural ability to eliminate heavy metals, particularly in cases where lead and cadmium exposure have taken their toll. Furthermore, these studies have tantalizingly hinted at the potential of molybdenum supplementation in mitigating the deleterious effects heavy metals inflict upon vital organs such as the liver, kidneys, and even the central nervous system. However, it must be noted that further research is required to determine the optimal dosages and long-term effects of molybdenum supplementation in the realm of heavy metal removal.

Limitations and considerations when using molybdenum for heavy metal removal

Though the prospects of molybdenum as a savior in the battle against heavy metal contamination are undeniably enticing, it is essential to bear in mind the limitations and considerations that accompany its usage. The efficacy of molybdenum in removing specific heavy metals may fluctuate depending on a myriad of factors, including the concentration and form of the metal itself, the pH levels of the environment, and the presence of other substances that may impede its noble mission. Additionally, it is crucial to approach molybdenum supplementation with a modicum of caution, as excessive intake can give rise to adverse health effects. It is, therefore, incumbent upon us to seek the counsel of healthcare professionals before embarking upon the path of molybdenum supplementation for the purpose of heavy metal removal.

III. How does molybdenum remove heavy metals?

Molybdenum, with its unique mechanisms and processes, plays a vital role in the removal of heavy metals. The key lies in the intricate dance of chemical reactions and interactions that molybdenum engages in with these heavy metal ions. When molybdenum encounters these ions, a series of transformative reactions take place, resulting in the creation of insoluble complexes or precipitates. These complexes, once formed, can be easily separated from the solution, effectively ridding it of the burden of heavy metals. However, the efficiency of molybdenum in this noble task is not without its dependencies.

The pH level, temperature, concentration of heavy metal ions, and the presence of other substances in the solution all conspire to influence the efficacy of molybdenum. Like a delicate symphony, these factors must be harmoniously balanced to achieve optimal results. Understanding these mechanisms and factors is of utmost importance, for it is through this understanding that the use of molybdenum in heavy metal removal processes can be refined and perfected.

IV. Benefits and drawbacks of employing molybdenum for the removal of heavy metals

Molybdenum has garnered recognition as an efficacious agent for the removal of heavy metals owing to its numerous advantages. Firstly, molybdenum-based methods exhibit a high degree of efficiency in purging contaminated water sources of heavy metals. Its strong affinity for these pollutants enables it to bind effectively, thereby reducing their concentration to safe levels. Moreover, molybdenum-based techniques are cost-effective and easily scalable, rendering them suitable for large-scale applications. Furthermore, molybdenum displays a remarkable selectivity towards heavy metals, minimizing any interference with other essential elements present in water. This selectivity ensures that the removal process does not engender further contamination or depletion of vital minerals. Additionally, molybdenum is environmentally friendly, as it does not engender the production of harmful byproducts during the removal process.

However, it is imperative to consider the potential drawbacks and limitations of employing molybdenum for the removal of heavy metals. One significant concern lies in the possibility of molybdenum leaching into the treated water, which can pose health risks if consumed in high concentrations. Hence, meticulous monitoring and control of molybdenum levels are crucial to ensure the safety of the treated water. Furthermore, the effectiveness of molybdenum-based methods may vary depending on the specific heavy metal contaminants present. Certain metals may possess a lower affinity for molybdenum, necessitating alternative removal techniques to achieve optimal results. Moreover, the implementation of molybdenum-based methods may necessitate specialized equipment and expertise, thereby augmenting the overall cost and complexity of the treatment process.

When comparing molybdenum-based methods with other techniques for the removal of heavy metals, several factors come into play. The efficiency and selectivity of molybdenum render it a favorable option in contrast to some conventional methods such as chemical precipitation or ion exchange. However, other advanced techniques like activated carbon adsorption or membrane filtration may offer superior performance in certain scenarios. The choice of the most suitable method hinges upon factors such as the specific heavy metal contaminants, water quality requirements, cost considerations, and the scale of the treatment operation. On the whole, molybdenum-based methods provide a promising solution for the removal of heavy metals, but careful evaluation and customization are necessary to ensure their optimal utilization.

V. Applications and industries utilizing molybdenum for heavy metal removal

Molybdenum, a versatile element with exceptional properties, is widely employed in various industries for the effective removal of heavy metals, thus addressing environmental concerns and ensuring the safety of diverse applications. Let us now explore the industries where molybdenum is commonly utilized for this purpose, and delve into specific applications and case studies that highlight its remarkable effectiveness. Furthermore, we shall discuss the future prospects and advancements in molybdenum-based technologies for heavy metal removal.

A. Examples of industries where molybdenum is commonly used for heavy metal removal

Molybdenum finds extensive use in several industries that necessitate efficient processes for the removal of heavy metals. One such industry is wastewater treatment, where molybdenum-based technologies play a pivotal role in eliminating harmful heavy metals before the water is discharged back into the environment. Another significant sector is mining, where molybdenum is employed to extract and separate valuable metals from ore, thus preventing the release of toxic substances into the environment. Additionally, molybdenum is widely utilized in the manufacturing of steel, as it aids in the removal of impurities and enhances the overall strength and corrosion resistance of the final product.

B. Specific applications and case studies showcasing molybdenum's effectiveness

The effectiveness of molybdenum in removing heavy metals can be witnessed through various specific applications and case studies. For instance, in the electronics industry, molybdenum is utilized in the production of semiconductors, where it assists in the elimination of heavy metal impurities, ensuring the reliability and performance of electronic devices. In another case, molybdenum-based catalysts have proven highly effective in reducing harmful emissions from automobile exhaust systems, thereby contributing to cleaner air and improved public health. Furthermore, the use of molybdenum in desalination plants has shown promising results in removing heavy metal contaminants from seawater, making it safe for consumption and irrigation.

C. Future prospects and advancements in molybdenum-based heavy metal removal technologies

The future of molybdenum-based technologies for heavy metal removal appears promising, with ongoing advancements and research in this field. Scientists and engineers are continuously exploring innovative methods to enhance the efficiency and effectiveness of molybdenum-based processes. These advancements include the development of new molybdenum-based adsorbents and membranes, which offer higher selectivity and capacity for the removal of heavy metals. Additionally, the integration of molybdenum-based technologies with renewable energy sources and sustainable practices is expected to revolutionize the field of heavy metal removal, ensuring a cleaner and safer environment for future generations.

Frequently Asked Questions

What is molybdenum?

Molybdenum is a chemical element with the symbol Mo and atomic number 42. It is a silvery-white metal that belongs to the group of transition metals. It has a high melting point and exceptional durability, making it suitable for various applications.

What are the characteristics of molybdenum?

Molybdenum is a refractory metal with a melting point of 2,623 degrees Celsius. It has a density of 10.28 grams per cubic centimeter and exhibits excellent thermal and electrical conductivity. It is also resistant to corrosion and does not react with hydrochloric acid or sulfuric acid at room temperature.

What are the common uses of molybdenum?

Molybdenum is used in the production of stainless steel to enhance its resistance to corrosion and strength at high temperatures. It is also used in the manufacturing of superalloys for jet engines and gas turbines. In the petroleum industry, molybdenum acts as a catalyst for the removal of sulfur from fuels. It is also used in electrical contacts, filaments, lubricant additives, and as a dry lubricant in high-friction environments.

Does molybdenum remove heavy metals?

Yes, molybdenum has the ability to remove heavy metals. It can bind with heavy metals such as lead, cadmium, and arsenic, facilitating their expulsion from water, soil, and industrial waste. Molybdenum acts as a catalyst in enzymatic reactions that aid in the detoxification and elimination of heavy metals from the human body.

How does molybdenum remove heavy metals?

Molybdenum removes heavy metals through a series of chemical reactions and interactions. It forms insoluble complexes or precipitates with heavy metal ions, which can then be separated from the solution. Factors such as pH level, temperature, concentration of heavy metal ions, and the presence of other substances influence the efficacy of molybdenum in heavy metal removal.

What are the benefits and drawbacks of using molybdenum for heavy metal removal?

Molybdenum-based methods for heavy metal removal offer advantages such as high efficiency, cost-effectiveness, selectivity towards heavy metals, and environmental friendliness. However, drawbacks include the possibility of molybdenum leaching into treated water, effectiveness varying depending on specific heavy metal contaminants, and the need for specialized equipment and expertise. The choice of removal method depends on factors such as the specific heavy metal contaminants, water quality requirements, cost considerations, and scale of the treatment operation.

Which industries utilize molybdenum for heavy metal removal?

Molybdenum is commonly used for heavy metal removal in industries such as wastewater treatment, mining, and steel manufacturing. It plays a crucial role in eliminating heavy metals from wastewater before it is discharged, extracting valuable metals from ore, and enhancing the strength and corrosion resistance of steel products.

What are some specific applications and case studies showcasing molybdenum's effectiveness in heavy metal removal?

Molybdenum is used in the electronics industry to eliminate heavy metal impurities in the production of semiconductors. It is also utilized as a catalyst in automobile exhaust systems to reduce harmful emissions. In desalination plants, molybdenum helps remove heavy metal contaminants from seawater, making it safe for consumption and irrigation.

What are the future prospects and advancements in molybdenum-based heavy metal removal technologies?

Ongoing advancements and research in molybdenum-based technologies for heavy metal removal include the development of new adsorbents and membranes with higher selectivity and capacity. Integration with renewable energy sources and sustainable practices is also expected to revolutionize the field, ensuring a cleaner and safer environment for future generations.