What is molybdenum metal?

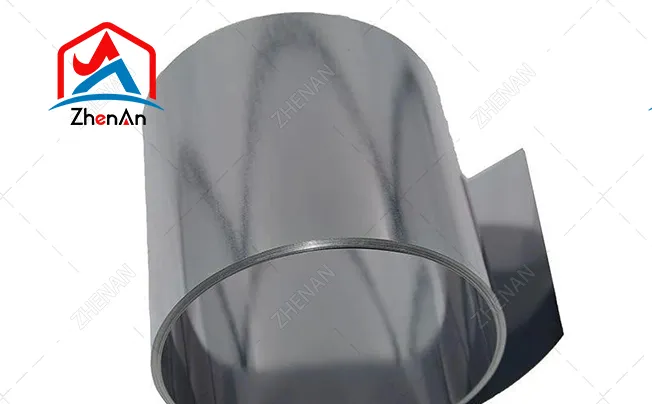

Molybdenum metal is a chemical element with the symbol Mo and atomic number 42. It has a lustrous, silvery-white appearance and is commonly found in minerals such as molybdenite. Known for its excellent melting point and excellent corrosion resistance, this metal is widely used in various industries.

Definition and characteristics of molybdenum metal

Molybdenum metal belongs to the well-known Group 6 of the periodic table of elements, indicating its status as a transition metal. It has a density of 10.28 grams per cubic centimeter and a melting point of an astonishing 2,623 degrees Celsius, making it one of the most heat-resistant metals. Molybdenum has excellent corrosion resistance, acid and alkali resistance, and a low thermal expansion coefficient. Additionally, it is an excellent conductor of electricity and has impressive tensile strength.

Common applications of molybdenum metal

Molybdenum metal has a variety of applications in different industries. Due to its extraordinary strength and high-temperature resistance, it is frequently used in the manufacture of high-temperature alloys, particularly those used in the aerospace and defense sectors. In addition, molybdenum is used as a catalyst in the petroleum industry and plays a key role in the production of sulfuric acid. Additionally, this versatile metal can be used to make electrical contacts and filaments for incandescent lamps. It is also an indispensable material for glass-melting electrodes. Finally, molybdenum is an important ingredient in the production of stainless steel, adding to its strength and increasing its resistance to corrosion.

"Is molybdenum metal safe?" is indeed a relevant question! Molybdenum metal does not pose major safety concerns. It is considered non-toxic and has minimal reactivity with other substances. However, as with any material, it is always prudent to handle it with care and follow appropriate safety protocols.

Is molybdenum metal safe?

Molybdenum is a metallic element widely used in various industries and has many beneficial properties. However, people should be aware of the potential health hazards associated with exposure to this substance. Molybdenum poses risks through inhalation, skin contact, and ingestion, so safety measures must be taken when handling this metal to mitigate any potential hazards.

Potential health hazards associated with molybdenum exposure

1. Inhalation risk: Inhaling molybdenum dust or smoke may cause respiratory illnesses such as coughing, shortness of breath, and chest tightness. Prolonged exposure to high levels of molybdenum can cause more serious respiratory problems.

2. Risk of skin contact: Direct contact with molybdenum in susceptible people can cause skin irritation, redness, and even dermatitis. To avoid these adverse effects, prolonged or repeated skin exposure to molybdenum must be avoided.

3. Ingestion risk: Ingestion of molybdenum compounds or metal fragments can cause gastrointestinal discomfort, nausea, vomiting, and diarrhea. Consuming large amounts of molybdenum over a long period may lead to more serious health complications.

Safety precautions when handling molybdenum metal

1. Personal Protective Equipment (PPE): When working with molybdenum, it is critical to wear appropriate personal protective equipment, including gloves, safety glasses, and respiratory protection when necessary. This helps minimize the risk of exposure through inhalation or skin contact.

2. Proper Ventilation and Containment: Ensuring adequate ventilation in the work area is critical to preventing the build-up of molybdenum dust or fumes. Additionally, the use of appropriate containment measures, such as enclosures or local exhaust ventilation systems, is critical to controlling the spread of molybdenum particles.

3. Safe Storage and Disposal Practices: Storing molybdenum in sealed containers in a cool, dry environment is critical to preventing oxidation and the potential release of hazardous substances. When disposing of molybdenum waste, local regulations and guidelines must be followed to ensure proper handling and minimize environmental impact.

Molybdenum Metal Safety Regulations and Guidelines

Molybdenum metal is an essential substance and its safety is regulated and guided by various respected organizations and institutions. With their profound knowledge and expertise, these authorities strive to promote protect individuals and the environment from potential hazards. Among these organizations, the following are particularly important:

Occupational Safety and Health Administration (OSHA) standards

The Occupational Safety and Health Administration (OSHA) is responsible for developing and enforcing workplace safety regulations within the United States. With an unwavering commitment to worker welfare, they have strict standards in place to mitigate the risks associated with molybdenum exposure. These standards include establishing Permissible Exposure Limits (PELs), which detail the maximum allowable concentration of molybdenum in workplace air. By adhering to these restrictions, employers can ensure the protection and well-being of their employees.

Environmental Protection Agency (EPA) Regulations

The Environmental Protection Agency, a respected agency dedicated to protecting human health and the environment, plays a vital role in the regulation of molybdenum metal. Recognizing the importance of maintaining a delicate ecological balance, the U.S. Environmental Protection Agency has promulgated regulations to control and monitor the release of molybdenum into the environment. These regulations are carefully designed to prevent excessive levels of molybdenum in the air, water, and soil. By doing so, they effectively maintain ecosystems and, in turn, protect public welfare.

International Agency for Research on Cancer (IARC) classification

Within the authority of the World Health Organization, the International Agency for Research on Cancer (IARC) has the key task of assessing the carcinogenicity of various substances. Molybdenum and its compounds are a subject of great interest and have been carefully evaluated by IARC. Their in-depth research and analysis classified molybdenum as a Class 2B substance – a possible carcinogen to humans. This classification, while not definitive, emphasizes the need for caution and further research to fully understand the potential risks associated with molybdenum exposure. Individuals must exercise caution and take appropriate steps to mitigate any potential harm.

Recommended Exposure Limits (REL) and Permissible Exposure Limits (PEL)

Respected organizations such as the National Institute for Occupational Safety and Health (NIOSH) have established the most important guidelines, such as Recommended Exposure Limits (REL) and Permissible Exposure Limits (PEL). These well-designed guidelines can serve as a shield to protect workers from harmful exposure hazards. By defining the maximum concentration of molybdenum to which workers can be exposed during a specific period, these limits effectively minimize the risk of adverse health effects associated with molybdenum exposure in occupational settings. Employers are unwaveringly committed to the well-being of their employees and should strictly adhere to these guidelines to ensure the safety of their employees.

Advantages and uses of molybdenum metal

Indeed, molybdenum metal does have a wide range of advantages and has multiple applications in various industries. Its unique properties make it a valuable material with many uses.

Industrial applications

Molybdenum metal plays a vital role in various industrial applications due to its excellent strength, high melting point, and corrosion resistance. It is commonly used in the production of heating elements, furnace components, and electrodes for electrically heated glass furnaces. In addition, molybdenum is used in the manufacture of crucibles, sintering boats, and thermocouple sheaths, making it an important material in the glass and ceramics industries.

Alloying agents in steel production

Molybdenum is widely used as an alloying agent in steel production to improve the mechanical and chemical properties of steel. By adding small amounts of molybdenum, steel becomes stronger, more resistant to corrosion, and better suited to high-temperature applications. This alloying element is particularly valuable in the construction of pipelines, oil and gas drilling equipment, and various structural components where durability and reliability are critical.

Catalysts and lubricants

Due to its catalytic properties, molybdenum is widely used as a catalyst in the chemical industry. It is used in fertilizer production, petroleum refining, and the manufacture of various chemicals. Additionally, molybdenum disulfide (a compound derived from molybdenum) acts as an excellent lubricant under extreme conditions. It is used in industries such as automotive, aerospace, and mining to reduce friction and wear is critical to equipment performance and longevity.

Other uses in electronics, aerospace, and energy sectors

Molybdenum metal is used in many cutting-edge industries. In electronics, molybdenum is used as thin films in the production of semiconductors and flat-panel displays. Its excellent thermal conductivity and low coefficient of thermal expansion make it ideal for these applications. Additionally, due to its high strength and resistance to extreme temperatures, molybdenum is used in aerospace applications, including rocket engines and aircraft parts. In the energy sector, molybdenum is used in the production of solar cells and as a neutron absorber and structural material in nuclear power plants.

Conclusion

In summary, it is important to consider safety factors when working with molybdenum metal. Understanding and following proper safety protocols is critical to ensuring a safe and protected work environment.

Summary of safety precautions for molybdenum metal

When handling molybdenum metal, several safety precautions must be kept in mind. First, it is important to recognize the potential dangers associated with molybdenum, such as its flammability and reactivity with certain substances. The presence of this metal requires caution and vigilance. Additionally, precautions must be taken to avoid inhaling or ingesting molybdenum dust or fumes as they may harm people's health by causing adverse health effects. Proper ventilation, personal protective equipment, and careful storage and handling procedures are essential to minimize risk and prevent any potential harm.

The importance of following proper safety protocols when handling molybdenum metal

The importance of following proper safety protocols when working with molybdenum metal cannot be overstated. This requires wearing appropriate protective equipment such as gloves, goggles, and a respirator to minimize direct contact and inhalation of molybdenum particles. By taking these precautions, people can protect themselves from the dangers molybdenum can pose. Additionally, adhering to safe handling practices, such as using designated containers for storage and disposal, will not only avoid accidents but also prevent any potential contamination. Regular training and awareness programs must be conducted to educate personnel on the potential risks associated with molybdenum and provide them with the necessary knowledge to effectively mitigate these risks. By putting safety first, the risks associated with handling molybdenum metal can be effectively managed, ensuring the well-being of all involved.

Is molybdenum metal safe?

Yes, molybdenum metal is considered safe to handle. It is non-toxic and has minimal reactivity with other substances. However, it is always important to handle it with care and follow proper safety protocols.

What are the potential health hazards associated with molybdenum exposure?

Exposure to molybdenum through inhalation, skin contact, or ingestion may pose health risks. Inhaling molybdenum dust or fumes can cause respiratory problems, while skin contact can cause irritation and dermatitis. Ingestion of molybdenum compounds or metal fragments can cause gastrointestinal upset. Prolonged or overexposure may cause more serious health complications.

What safety precautions should be taken when handling molybdenum metal?

When handling molybdenum metal, always wear personal protective equipment (PPE) such as gloves, safety glasses, and respiratory protection if necessary. Adequate ventilation and containment measures should be taken to prevent the accumulation of molybdenum dust or fumes. Proper storage in sealed containers and compliance with disposal regulations are also important safety measures.

What are the regulations and guidelines for molybdenum metal safety?

The safety of molybdenum metal is regulated and guided by organizations such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). OSHA establishes workplace safety regulations, including permissible exposure limits (PELs) for molybdenum. The EPA regulates the release of molybdenum into the environment. The International Agency for Research on Cancer (IARC) lists molybdenum as a potential carcinogen. Organizations such as the National Institute for Occupational Safety and Health (NIOSH) have developed Recommended Exposure Limits (REL) and Permissible Exposure Limits (PEL) to protect workers from harmful exposures.

What are the advantages and uses of molybdenum metal?

Molybdenum metal has many advantages and can be used for communication in various industries. It is used in industrial applications such as heating elements and furnace components. It is also used as an alloying agent in steel production to increase strength and corrosion resistance. Molybdenum is used as a catalyst in the chemical industry and as a lubricant under extreme conditions. It also has applications in electronics, aerospace, and energy.

Conclusion

When working with molybdenum metal, it is important to prioritize safety and follow proper protocols. Understanding potential health hazards, adhering to safety precautions, and adhering to regulations and guidelines are critical to a safe work environment.