Definition of molybdenum foil

Molybdenum foil is a delicate, elongated sheet made from the wonderful chemical element molybdenum. This silvery-white transition metal has an atomic number of 42 and the symbol Mo appears on the periodic table, and its remarkable qualities have attracted the attention of many. Its high melting point, excellent strength and unwavering corrosion resistance make it an invaluable substance in various industries.

What is the use of this molybdenum foil? Allow me to inspire you, for its practicality is as fascinating as the element itself. This fine foil is usually made through a delicate process called rolling, in which the molybdenum is cleverly transformed into thin sheets, ranging in thickness from a few microns to several millimeters.

The applications of molybdenum foil are diverse. In electronics, it is a key component in the production of semiconductors, transistors and even integrated circuits. Its excellent electrical conductivity and thermal resistance make it ideal for such complex equipment, ensuring optimal performance.

But that’s not all, as molybdenum foils also play a vital role in aerospace engineering. Its exceptional strength and ability to withstand extreme temperatures make it an indispensable material in the construction of aircraft components such as wings and fuselages. This elastic foil ensures the safety and durability of these flying marvels, allowing them to traverse the sky with grace and precision.

In addition, molybdenum foil also has a place in the medical field. Its biocompatibility and corrosion resistance make it an excellent choice for surgical implants such as pacemakers and artificial joints. My dear reader, this extraordinary material has not only improved the quality of life for countless people, but also ensured the success and longevity of these life-saving surgeries.

What are the uses of molybdenum foil? From the fields of electronics and aerospace engineering to the medical field, this exquisite molybdenum sheet has the power to revolutionize industry and improve life. Its presence, although often invisible, is an integral force driving progress and innovation in our ever-evolving world.

The application of molybdenum foil: the miracle of modern industry

This substance has found its place in various industries due to its performance and properties. Explore its applications in electronics, aerospace and medicine.

Electrical conductivity: Molybdenum foil in the electronics industry

The electronics industry, which is constantly pursuing innovation, cherishes the excellent conductivity of molybdenum foil. This foil has an elegance unmatched by any other material, and its efficiency in conducting electricity is unparalleled. Its impressive electrical conductivity enables seamless transmission of electrical signals, making it an indispensable component in circuit board, semiconductor and thin-film transistor manufacturing. These electronic marvels owe their reliable performance and enhanced functionality to the extraordinary electrical properties of molybdenum foil.

Molybdenum foil in aerospace industry

The aerospace industry has taken off to new heights, relying on the unwavering power of molybdenum foil. With a melting point that pushes the boundaries of possibility and strength to withstand the harshest mechanical stresses, the foil is a beacon of reliability. Its presence graces the structure of rocket nozzles, aircraft engine parts and heat shields, increasing the resistance of these vital components to the relentless forces of extreme temperatures and mechanical strain. The aerospace industry owes its safety and performance to the unwavering durability of molybdenum foil.

Molybdenum foil in the medical field

In the medical field, molybdenum foil plays a vital role due to its biocompatibility and corrosion resistance. These exceptional properties make it a trusted ally in the creation of a variety of medical devices and procedures. The longevity of implants such as pacemakers and artificial joints is due to the unwavering stability of molybdenum foil, which bravely withstands the corrosive environment of the human body. Furthermore, its biocompatibility ensures minimal adverse reactions when in contact with delicate biological tissues. The medical industry followsWith an unwavering commitment to patient care, we are delighted by the unique properties of molybdenum foil, which advances medical care and improves the lives of countless people.

Advantages of using molybdenum foil

Molybdenum foil is a favored material in a variety of industries and offers many advantages. These advantages, prized by discerning individuals, include:

High temperature resistance and thermal conductivity

Molybdenum foil has excellent resistance to the hottest temperatures, making it suitable for applications requiring the highest temperatures. Its melting point is as high as 2,623 degrees Celsius, ensuring its structural integrity remains stable even in the most intense inferno.

Mechanical properties and strength

Another commendable attribute of molybdenum foil is its excellent mechanical properties and tenacious strength. It has tensile strength second to none, resists deformation and can withstand heavy loads. Additionally, molybdenum foil is impressively malleable and can be effortlessly molded into a variety of shapes without compromising its structural integrity.

Corrosion-resistant, compatible with human body

Molybdenum foil does not corrode, making it suitable for deployment in corrosive environments. It remains unyielding in the face of acids, alkalis and other corrosive agents, escaping unscathed from their vicious clutches. Additionally, molybdenum has excellent biocompatibility, ensuring its safety in medical and dental applications such as implants and prosthetics, as it harmonizes seamlessly with the human body.

What is the use of molybdenum foil?

Now one can think about the practical applications of this venerable material. Molybdenum foil is used across many industries. Its high temperature resistance and thermal conductivity make it indispensable in aerospace engineering, where it is used to build heat shields and rocket nozzles. In addition, its excellent mechanical properties and strength make it invaluable in the manufacture of electrical contacts, heating elements and furnace components. In the medical field, molybdenum foil shines, finding a place in medical implants and dentures due to its corrosion resistance and biocompatibility.

Uses of molybdenum foil

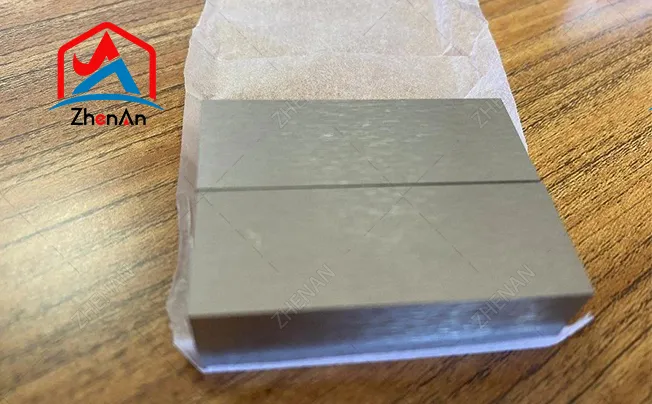

Molybdenum foil is produced through a careful manufacturing process and has many uses. Its journey begins with extracting molybdenum metal from its ore, a process that requires extreme care and precision. Once obtained, molybdenum metal undergoes a series of transformations.

First, the metal is heated and transformed into a fine powder that resembles the delicate feel of freshly fallen snow. This powder is carefully pressed and sintered to form a strong and solid block of solid molybdenum. However, the block’s journey has just begun.

By the skilled hands of craftsmen, the blocks are rolled and stretched using a series of rolling mills. This painstaking process, reminiscent of a dance, gradually reduces the thickness of the block, transforming it into molybdenum foil. Resembling the flapping of a butterfly's wings, this delicate material emerges ready to fulfill its purpose.

Advantages of molybdenum foil

Molybdenum foil, with its exquisite craftsmanship and rich physical and chemical properties, has immeasurable value in various industries. Its superior thermal and electrical conductivity make it a coveted choice in high-temperature environments, and its stability shines like a guiding light.

In addition, molybdenum foil has tremendous strength and durability, allowing it to withstand the burden of mechanical stress and deformation. Like a knight in armor, it stands firm against the test of its surroundings.

Not only is this material elastic, it also exhibits excellent corrosion resistance. Harsh chemicals and unforgiving environments may attack it, but it remains steadfast and refuses to succumb to their destructive power.

In addition, the low thermal expansion coefficient of molybdenum foil makes it stable and reliable, ensuring its stable performance under various conditions.

It is therefore no surprise that molybdenum foil has found a place in industries such as electronics, aerospace and energy. Its versatility and stability make it an indispensable asset in the pursuit of progress and innovation.

Precautions when using molybdenum foil

Molybdenum foil is a versatile material with a wide range of uses. But it must be handled with care and caution to avoid causing harm. Additionally, understanding its compatibility with other materials and substances is critical to ensuring its optimal performance. Finally, be sure to take the necessary safety precautions when working with this precious foil to minimize any potential risks. Please allow me to elaborate on these considerations to give you a comprehensive understanding of the use of molybdenum foil.

A. Proper handling and storage to prevent damage

Molybdenum foil can only maintain its integrity if it is handled and stored with the utmost care. Clean gloves or tools must be used when handling this fragile material, as any contamination may cause adverse consequences. Additionally, sharp or abrasive objects must be kept at a distance to avoid them leaving unsightly scratches or tears on the foil surface. As for storage, a dry and controlled environment is essential to protect aluminum foil from the dangers of moisture. Because moisture can cause oxidation and degradation, rendering the foil ineffective. Oh, and how smart it is to store the foil in a protective box or wrap it in a non-reactive material to provide an extra layer of protection.

B. Compatibility with other materials and substances

Understanding the compatibility of molybdenum foil with other materials and substances is critical to its successful application. This beautiful foil has excellent high temperature resistance and is compatible with many metals and alloys. However, caution must be exercised as certain chemicals or corrosive substances may cause degradation or loss of performance. Before using molybdenum foil, its compatibility with the intended environment or application should be carefully evaluated. Dear reader, consulting the material compatibility chart or seeking expert advice will ensure proper selection and use of molybdenum foil.

C. Safety precautions when using molybdenum foil

Working with molybdenum foil requires observing safety precautions to minimize potential risks. This foil is as sharp as a needle and can easily puncture skin, so appropriate protective gear such as gloves and safety glasses is essential. When embarking on the task of cutting or shaping foil, proper tools and techniques must be used to avoid any accidents. Additionally, it is recommended to do this in a well-ventilated area or to wear respiratory protection, especially if dust or fumes are generated. Dear readers, let us not forget the importance of following the safety guidelines and protocols given to us by the manufacturer or regulatory agency, as they are key to creating a safe working environment when handling molybdenum foil.