Recent Product Posts

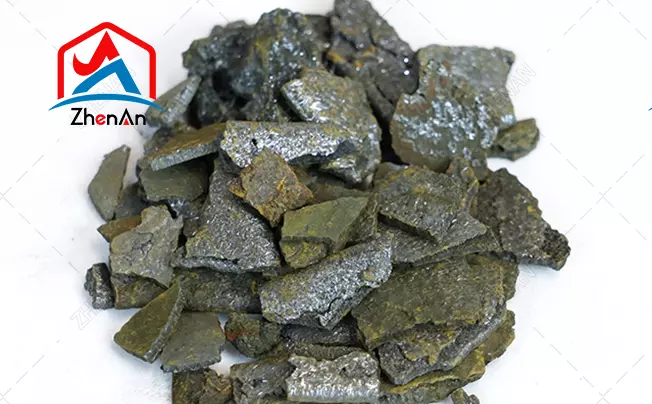

Flake vanadium pentoxide, also known as vanadium anhydride, appears as gray-black flakes.

Vanadium Pentoxide Flake

Vanadium Pentoxide Flake Description

Flake vanadium pentoxide, also known as vanadium anhydride, appears as gray-black flakes.

Vanadium Pentoxide Flake Parameters

| Model | Flake Vanadium pentoxide |

| Material | V2O5 |

| Function | Alloy additive |

| Diameter size | Width 20-80mm; Thickness 2-8mm |

| The Highest Grade Vanadium Pentoxide Flake | |

| Packing: 250kg steel drum | |

| Shape: Fused Flake Type | |

| Sales Quantity: 500MT/month | |

| * The above production quantity depends on the metal content of the waste catalyst. | |

Vanadium Pentoxide Flake Advantages

Vanadium pentoxide electrofusion sheet series amphoteric oxides, under acidic conditions, the color is yellow to rust-colored crystals. As a toxic substance in the air, the maximum allowable amount is less than 0.5mg/m3.

Mainly used to make electric furnace electrode paint, or added to steel for special steel; can be used as a contact agent in the glass and ceramic industries.

Manufacture And Use of Vanadium Pentoxide Flake

Vanadium flakes are mainly used in the steel industry. By refining the structure and grains of the steel, the grain coarsening temperature increases, thereby improving the strength, toughness, and wear resistance of the steel. In addition, vanadium flakes have excellent improvement effects in titanium alloys and are used as additives in the aerospace field.

Vanadium Pentoxide Flake Applications

Competitive Advantage

Unparalleled expertise: With thirty years of practical experience we have an unparalleled understanding of the metalworking process, ensuring top quality in all our products.

Extensive product range: Our diverse product portfolio caters to various industrial needs, making us a one-stop solution for every metallurgical requirement

Quality Assurance: We implement strict quality control measures at every stage of production to ensure our products meet or exceed industry standards.

Customization: We understand that each customer's needs are unique. Our flexible production capabilities allow us to customize products to specific requirements

Global influence: With an extensive international trade network and experience, we promote the Wufeng import and export business, covering customers around the world.

Commitment to Sustainability: We attach great importance to sustainable practices in our production processes and strive to minimize our impact on the environment.

* We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.